High-Pressure Hydraulic Oil Extraction Machine

Cold Press Oil Machine | Nut Oil Extraction Machine

Capacity: 12-180kg/h

Barrel capacity: 2-45kg

Oil cake diameter: 155-460mm

Application: Pressing sesame oil, walnut oil, olive oil, etc.

Heating temp: 70–90℃

Working pressure: 55–60MPa

The oil extraction machine uses a purely physical pressing method, which can cold-press sesame seeds and corns as well as hot-press walnuts, olives, and macadamia nuts. The machine operates at up to 60 MPa, efficiently extracting oil while preserving nutrients and flavor.

Its hourly output varies from 12 to 180 kg depending on the model, with a controllable heating temperature between 70℃ and 90℃. The cold-press oil machine is easy to operate with a simple instruction manual. One person can operate 3-4 units at the same time.

Key advantages of the oil extraction machine

- Taizy oil press machine has a high oil extraction rate: 43%–47% for sesame seeds and 50%–60% for walnuts.

- The oil quality is excellent, using a cold-pressing process to maximize the preservation of natural nutrients and active compounds. It produces low-impurity, clear oil and high-value oil cakes.

- Equipped with an ultra-high-pressure system, its maximum pressure can reach 60 MPa, providing a continuous and stable pressing force, suitable for hard and soft oily materials.

- It can simultaneously perform both hot and cold pressing with a wide range of applications.

- This oil extraction machine uses a mechatronics design, has a low failure rate, a high degree of automation, and can be operated by one person.

Working principle of the oil extraction machine

This oil extraction machine operates based on the liquid static pressure transmission principle. Using Hydraulic oil as the pressure transmission medium, an ultra-high-pressure hydraulic system applies uniform pressure to the oil materials

Oilseeds are extracted through pure physical pressing, maximizing the extraction of natural oils without the addition of any chemical additives.

The entire system consists of a hydraulic power unit and a sealed pressing chamber, forming a closed-loop hydraulic circuit. This ensures that the hydraulic oil circulates continuously within the system, significantly extending the machine’s lifespan.

This system allows the machine to automatically control pressure during operation. When the pressure reaches 55–60 MPa, the machine automatically stops. After the pressure drops, the machine automatically restarts, ensuring efficient and safe oil extraction.

How to use the oil press machine?

Step 1: Turn on the power and check the indicator lights. (For first-time use, turn the machine on and off 10 times to purge air from the hydraulic system and set the heating temperature to 50–60°C.)

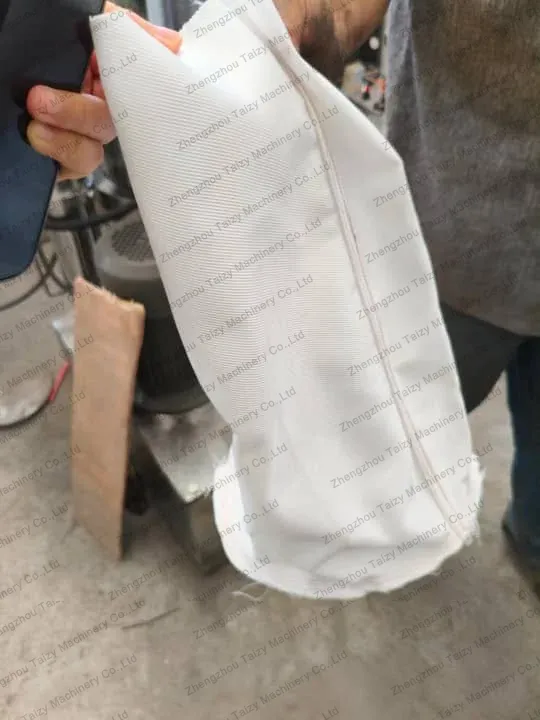

Step 2: Carefully lift the piston (do not exceed the safe height) and place a cotton filter pad at the bottom.

Add the roasted oil and place another cotton pad and the pressure plate.

Step 3: Start the machine and begin pressing. After 2–3 pressure cycles, remove the oil cake and slowly release the pressure.

Note: Before starting the next cycle, fully lower the piston. The oil filter bag usually needs to be replaced after a few uses.

Technical Specifications of Oil Extraction Machine

We offer a variety of styles to suit different production needs. You can choose according to your actual production needs.

If you are unsure which option is best for you, please provide your raw material and production requirements, and our professionals will provide you with a solution based on your information.

| Model | TZ-150 | TZ-180 | TZ-230 | TZ-260 | TZ-320 | TZ-360 | TZ-415 | TZ-460 |

|---|---|---|---|---|---|---|---|---|

| Capacity | 12kg/h | 20kg/h | 40kg/h | 60kg/h | 70kg/h | 90kg/h | 120kg/h | 180kg/h |

| Barrel capacity | 2kg | 4kg | 8kg | 12kg | 17.5kg | 22.5kg | 30kg | 45kg |

| Oil cake diameter | 155mm | 192mm | 242mm | 268mm | 323mm | 370mm | 415mm | 460mm |

| Motor power | 0.75 kW | 1.5 kW | 1.5 kW | 1.5 kW | 2.2 kW | 2.2 kW | 2.2 kW | 3 kW |

| Heating power | 600 W | 720 W | 850 W | 950 W | 1100 W | 1250 W | 1500 W | 2000 W |

| Heating temp | 70–90℃ | 70–90℃ | 70–90℃ | 70–90℃ | 70–90℃ | 70–90℃ | 70–90℃ | 70–90℃ |

| Working pressure | 55–60MPa | 55–60MPa | 55–60MPa | 55–60MPa | 55–60MPa | 55–60MPa | 55–60MPa | 55–60MPa |

| Weight | 240kg | 550kg | 950kg | 1200kg | 1700kg | 2000kg | 2200kg | 3000kg |

Note: Actual oil extraction rate may vary depending on raw material quality, moisture content, and pressing method (cold press or hot press).

Wide range of applications of the oil extraction machine

This oil press supports both hot and cold pressing methods and is suitable for a variety of raw materials:

Hot-pressed edible oil:

- Sesame

- Flaxseed

- Peanuts

- Wheat germ

- Corn germ

Cold-press healthy oils:

- Walnuts

- Pine nuts

- Almonds

- Sunflower seeds

- Olives

- Macadamia nuts

- Camellia seeds

Spices and herbs oil extraction:

- Sichuan pepper

- Mustard seeds

- Perilla seeds

- Traditional Chinese medicine herbs

Below is a table showing the oil rate of some materials:

| Raw material | Oil extraction range |

|---|---|

| Sesame seeds | 43% – 47% |

| Walnut kernels | 50% – 60% |

| Peanut kernels | 18% – 22% |

| Tea seeds (Camellia seeds) | 25% – 29% |

How to use an oil press safely?

- After one month of use for a new machine, the hydraulic oil must be thoroughly filtered and the oil tank cleaned. Thereafter, the hydraulic oil should be changed annually.

- To ensure the safe operation of the electrical system, grounding protection measures must be taken.

- The hydraulic system of this machine is of ultra-high pressure, with a maximum pressure of 60 MPa. Overpressure operation is strictly prohibited.

- The roasted oilseeds need to be vented before pressing; otherwise, a gas explosion may occur during oil pressing, which could cause serious injury.

- After the oilseeds are pressed dry, the oil cake must be removed immediately; otherwise, a gas explosion may occur if left for too long.

Causes and solutions for machine malfunctions

If the nut oil press machine’s pressure gauge pointer does not rise, or if it cannot reach high pressure, the following are some possible problems and their solutions:

| Possible cause | Solution |

|---|---|

| Foreign matter enters the pump, preventing the steel ball in the inlet valve from returning to its original position | The oil seal inside the hydraulic cylinder is damaged |

| Clean foreign matter inside the pump and replace it with clean hydraulic oil | Disassemble the manual valve on the pump station and clean the manual valve |

| The piston is severely worn | Replace with a new oil seal |

| Oil pipe joints are leaking, and the sealing is not tight | Replace sealing components and tighten bolts securely |

| The pressure gauge is damaged and the needle does not move | Replace with a new piston |

| The pressure gauge is damaged, and the needle does not move | Replace with a new pressure gauge |

If you are looking for reliable oil presses for cold or hot pressing oil production, contact us for more information and discounts.

If you want to produce larger quantities of commercial oil, we recommend this oil press: Peanut Oil Extraction Machine, which also provides a cold-press and hot-press extraction system.