Peanut Cutting Machine For Nut Chopping

Nut Chopping Machine | Cashew Cutter

Capacity: 200–300 kg/h

Voltage: 380 V 50 Hz

Finished product: Crushed nuts, crushed cookies(adjustable granule size)

Top-selling countries: India, Argentina, Malaysia, Nigeria, etc.

Material: Stainless steel and carbon steel.

This peanut cutting machine is designed to produce evenly sized granules of peanuts, cashews, and other nuts, with a capacity of up to 200-300 kg/hour. Its consistent output and high-quality finished products make it an ideal choice for the baking, confectionery, snack, and food processing industries.

Key features of an industrial peanut cutting machine

- Our badam cutting machine’s blade gap can be freely adjusted according to the size of the final product requirements. Only one machine can complete the production of multiple particle sizes, effectively reducing equipment purchase costs.

- After the upgrade, our improved shredding structure with low material consumption and low oil pollution can reduce the proportion of crushed powder when processing peanuts and nuts, thereby reducing raw material loss and increasing profits.

- This groundnut chopping equipment is equipped with a multi-layer vibrating screen. Its screens with different aperture sizes can automatically separate particles that meet the specifications, making the particle size more uniform.

Main applications of the nut chopping machine

Besides peanuts, it can also cut walnuts, macadamia nuts, etc., which are widely used in the food industry as popular ingredients. Many bakeries use it as a topping for bread, a filling for cakes, and as a pastry filling. It not only enhances the taste and chewiness but also improves the product’s appearance.

In addition, it is also an indispensable ingredient in candy and snack production as well as in food accompaniment. Both pre-mixed ingredient packets used in snack production and flavor-enhancing ingredients processed for kitchen use require chopped nuts as a raw material.

How does the peanut cutting machine work?

The peanut cutting machine operates through a combination of feeding, slicing, and grading systems.

Step 1: Before starting the operation, check that all equipment components are functioning properly and start the machine in the correct sequence: Start the vibrating screen or grading screen, then start the cutting blades. (To shut down, reverse the sequence.)

Step 2: Pour the prepared material into the hopper. Adjust the hopper gate opening and feed belt speed to ensure the feed speed matches the cutting speed correctly. (Even feeding results in better cutting consistency.)

Step 3: After cutting, the processed nuts fall directly into the grading screen. Different screens separate the particles into multiple size grades. If you want a different particle size, the screen plate can be changed to meet your needs.

Models and parameters of the groundnut chopper machine

We offer two different models, each with a different internal structure. In addition, the two differ significantly in cutting methods, finished product shape, applicable scope, and maintenance costs.

Straight-blade type automatic cashew cutting machine

This peanut granulator uses a high-speed reciprocating straight blade to cut peanuts, resulting in clean cuts and more square-shaped kernels. The granulation effect is controlled by the sharpness of the blades and their speed.

| Capacity | 200–300 kg/h |

| Voltage | 380 V |

| Total power | 2.25 kW |

| Frequency | 50 Hz |

| Dimensions | 2250*1050*1400 mm |

| Weight | 400 kg |

| Cutting structure | Straight reciprocating blades |

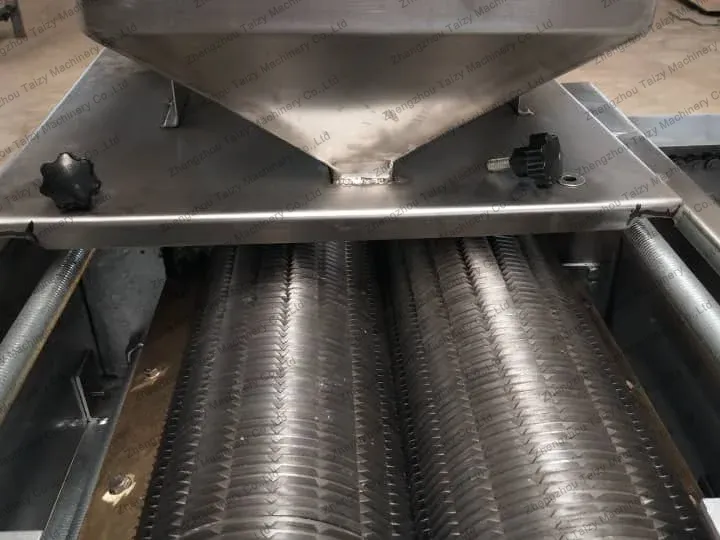

Roller-cutter type peanut cutting machine

The roller-type nut pellets are produced by extruding and cutting nuts using multiple sets of rollers and rollers. The pellets are mostly three-dimensional with a more natural shape.

| Capacity | 200-300 kg/h |

| Voltage | 380 V |

| Total power | 0.93 kW |

| Frequency | 50 Hz |

| Dimensions | 1600*800*1500 mm |

| Weight | 300 kg |

| Cutting structure | Multi-roller cutting system |

If you are having trouble deciding which peanut cutting machine is right for you, you can provide our customer service with your finished product and requirements, and we will provide you with the most suitable one.

Malaysian customers use nut cutters to produce high-quality macadamia nut kernels

A Malaysian customer upgraded its macadamia nut production line by purchasing a 200-300 kg/hour stainless steel nut cutter to cut nut pieces of 5 mm, 6 mm, and 8 mm.

Because macadamia nuts are high in oil and hard, they are more difficult to cut than peanuts and almonds, requiring sharper blades and more stable equipment. Furthermore, our customers need different sizes of finished products for different product lines:

- 5mm → Chocolate blends

- 6mm → Energy bars, baking fillings

- 8mm → Premium nut snack ingredients

These requirements make it difficult for our customers to find high-quality machines at a reasonable price. After several discussions, we recommended the following configuration of the macadamia nut granulator to our customer:

| Capacity | 200–300 kg/h |

| Voltage | 380 V 50 Hz |

| Total power | 2.25 kW |

| Dimensions | 2860×800×1400 mm |

| Weight | 400 kg |

| Material | Hopper, sieve & all food-contact parts are stainless steel |

| Final granule size | 5 mm / 6 mm / 8 mm adjustable |

Finally, with the remote guidance of our engineers, this nut chopping machine was successfully put into use on the production line, and our customers were very satisfied with its output and finished products.

If you are interested in our cashew cutter, please contact us for the latest price and more working videos!

Other peanut processing machines: Peanut Roasting Machine, Peanut Peeling Machine, etc.