Nut Chopping Machine | Industrial Nut Cutting & Granulating Solution

Badam Cutting Machine | Almond Chopping Machine

Power: 2.25 kw

Capacity: 200–500 kg/h

Number of knives: 10 pcs

Screening system: Three-stage screen, four size grades

Voltage: 380 V

Frequency: 50 Hz

Hot-selling countries: Turkey, Egypt, the United States, etc.

Taizy nut chopping machine is widely used in nut processing plants and raw material pretreatment production lines that require precise control of particle size. It can efficiently and stably chop various nuts (such as peanuts, almonds, etc.) and legumes into uniform particles with a capacity of 200–500 kg/h.

The nut cutting machine integrates a stable mechanical structure, adjustable cutting precision, and multi-stage screening functions. It can be purchased separately for nut processing or connected to a production line to effectively improve the efficiency of industrial peanut food production.

Key features of the badam cutting machine

- The frame of this nut chopping machine is made of thick channel steel, resulting in a heavy overall weight and minimal vibration during operation, effectively preventing deformation caused by prolonged use.

- Its main castings are made of QT500-7 ductile iron, which gives the entire machine high tensile strength and excellent wear resistance. The self-lubricating properties of ductile iron also reduce friction and lower maintenance costs.

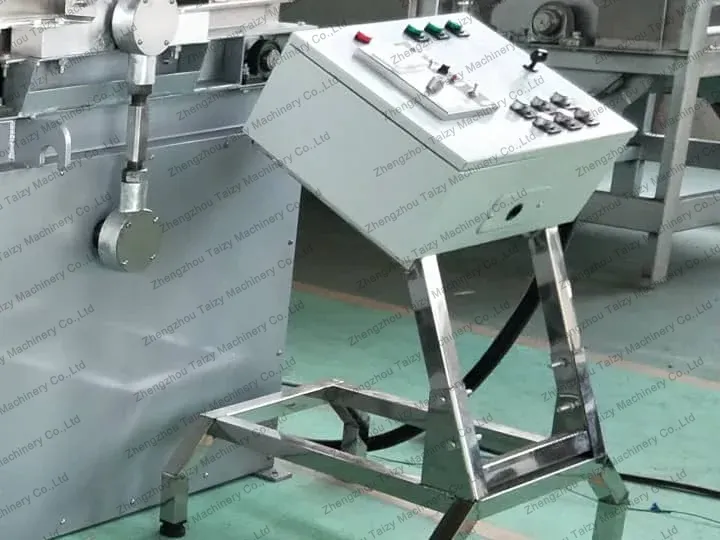

- It features an independent electrical control cabinet, effectively preventing damage to electrical components due to machine vibration. This also improves operational safety and facilitates daily operation and maintenance.

- The peanut cutting machine has a three-stage screening system with four output grades. Its simple structure makes it easy to disassemble and clean, making it particularly suitable for food factories with frequent product changes.

- Its body is made of carbon steel with a powder coating surface for good corrosion resistance. Material contact parts are designed using food-grade stainless steel, meeting the basic hygiene requirements for food processing applications.

How does the nut chopping machine work?

The nut chopping machine uses a continuous feeding method, performing reciprocating cutting on the material on the conveyor belt, and then separating the processed pieces by particle size using a vibrating screening system.

1. Uniform feeding

Raw materials such as peanuts, almonds, walnuts, or hazelnuts are uniformly fed from the hopper onto the conveyor belt. The conveyor belt speed is adjustable. (For optimal chopping results, the speed should not be set too fast.)

2. Reciprocating cutting system

The material is conveyed to the cutting chamber, where 10 reciprocating cutting blades continuously chop the nuts. (The cutting speed of the blades is kept constant to ensure stable cutting performance.)

3. Adjustable particle size

The final particle size can be controlled by adjusting the conveyor belt speed.

- Faster conveyor belt speed → Fewer cuts → Larger particles

- Slower conveyor belt speed → More cuts → Smaller particles

4. Vibrating Screening

After chopping, the material enters a three-layer vibrating screen, separating the product into four different particle size grades to meet various product specifications.

This cold cutting process perfectly preserves the original flavor, texture, and nutritional value of the nuts. It is ideal for the pretreatment of nut-based foods.

Applications of Taizy nut cutting machine

Nut choppers are widely used in the food processing and ingredient preparation industries, especially in production lines that require chopping nuts or legumes into uniform and controllable particle sizes.

This machine is ideal for chopping and granulating various nuts, including peanuts, almonds, walnuts, hazelnuts, and chestnuts. The chopped nut particles are commonly used in nut ingredients (for desserts or bread baking) and mixed nut snacks.

In central kitchens and food ingredient factories, nut choppers can be used for the batch pre-processing and grading of nut raw materials, providing a continuous and stable supply of different-sized nut particles for downstream processing lines.

Furthermore, it can be paired with a peanut roasting machine. Roasting the peanuts before cutting them into pieces results in a better color and flavor. Some customers who purchase Taizy’s peanut candy production line also request a cutting machine to enhance the texture of the peanut candy.

Technical specifications of nut chopper

| Power | 2.25 kW |

| Capacity | 200–500 kg/h |

| Number of knives | 10 pcs |

| Screening system | Three-stage screen, four size grades |

| Voltage | 380 V |

| Frequency | 50 Hz |

| Machine size | 2820 × 950 × 1300 mm |

| Frame material | Powder-coated carbon steel |

| Contact material | 201 stainless steel |

Some parameters are not fixed and can be adjusted according to specific needs, such as the material composition of the machine and the voltage. We will customize the product according to the customer’s specific requirements.

What can Taizy offer you?

Due to varying customer needs, we also offer a variety of services to make you satisfied, including:

Material customization

We offer options for the material in contact with the product, with the outer panels available in 304 or 316 stainless steel, and the frame available in a 304+201 mixed material or 316 stainless steel.

One-on-one professional customization

Taizy will recommend the most suitable equipment based on the materials you need to process and the desired final results. If you have other needs, we can also help you customize a production line for nut processing.

Transparent price list

We own our own factory, guaranteeing you high-quality machines at an excellent value. Each of our nut processing machines complies with CE and other export certifications and comes with a 12-month warranty.

High-quality after-sales service

After the order is completed, our customers enjoy lifelong after-sales service, including remote technical support and long-term spare parts supply.

If you have any further questions or would like to inquire about other information regarding this nut chopping machine, please contact us for the latest updates!