Almond Peeling Machine Solution For Austria

An Austrian client planned to enter the almond product market, aiming to process raw almonds into value-added products such as peeled almonds, almond slices, etc.

However, in the early stages of the project, the client faced a common challenge: while they had a clear business idea, they were unsure which machines they needed and how to efficiently organize the production process.

Therefore, the client contacted us seeking expert advice on almond processing equipment and production solutions.

Client’s needs and challenges

After in-depth communication, the client clearly expressed their desire to start a small-to-medium-sized almond processing business, processing raw almonds into peeled almond slices and then packaging them into finished almond products.

They hoped we could recommend the necessary equipment to avoid unnecessary investment. For this client, the key challenge was not price, but how to build a complete and practical almond processing solution from scratch.

Taizy solution: Complete almond processing production line solution recommendation

Based on the client’s raw materials, target products, and future expansion plans, Taizy provides a customized almond processing solution, including the following core equipment:

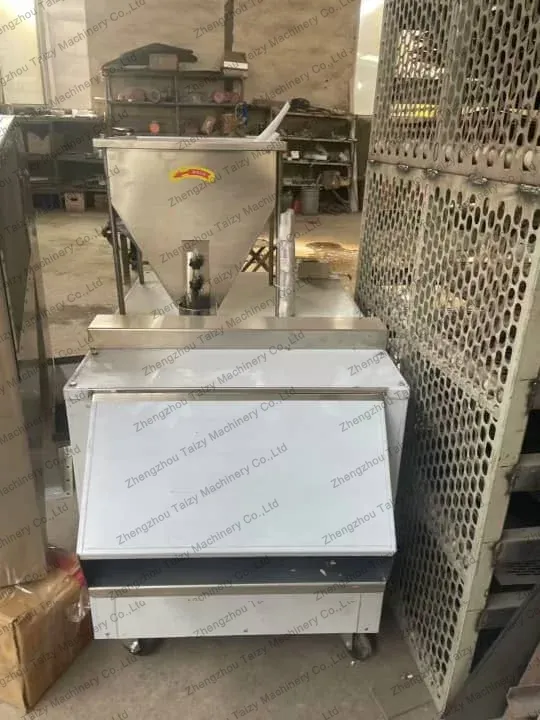

Almond peeling machine

The almond peeling machine is one of the most critical pieces of equipment in the production line. It effectively removes almond skins without damaging the kernels. It also boasts the following significant advantages:

- High peeling rate (96%), minimal almond damage (≤ 6%)

- Easy operation and maintenance

- Can be used in conjunction with other production lines for upgrades

This equipment helps clients quickly upgrade raw almonds into higher-value peeled almond products.

Almond slicer

To meet our customers’ advanced processing requirements, we recommend an almond slicer. This slicer is often used in conjunction with an almond peeling machine, which is one of our best-selling combinations:

- Adjustable slice thickness between 0.3 mm and 2 mm

- Even slicing produces 50-300 kg of almond slices per hour.

Help customers produce almond slices widely used in baking, cereal, and confectionery products.

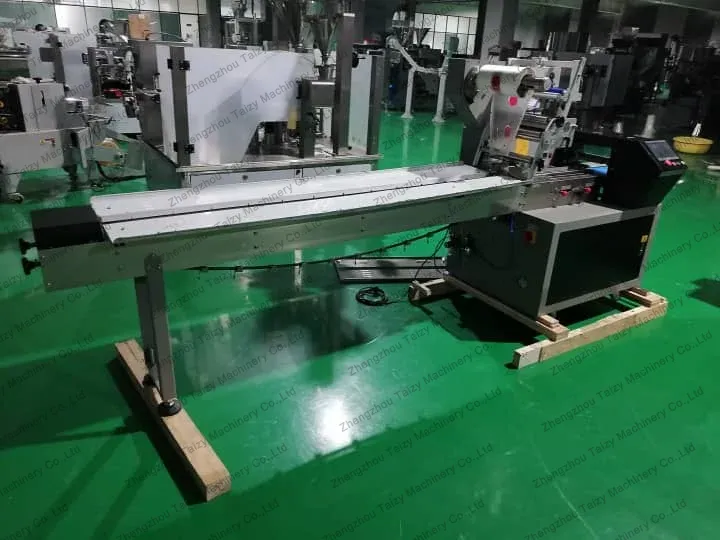

Pillow packaging machine

To streamline the production process and prepare for retail, our solution includes a pillow packaging machine, which directly packages the processed products. Customers can supply directly to supermarkets, wholesalers, and online markets.

Project result: From idea to practical almond processing line

With the equipment and solutions recommended by Taizy, the client successfully established a complete almond processing production line, including:

Almond peeling

Almond slicing

Finished product packaging

After the machine was tested and packaged, it was immediately shipped to Austria and eventually arrived at the customer’s factory.

This solution enabled the client to smoothly enter the almond product market, laying a solid foundation for future business growth.

Conclusion: Taizy Helps You Build a Complete Almond Processing Solution

Taizy is not just a supplier of machines, but focuses on helping customers build practical processing solutions.

Whether you are starting a nut processing business or upgrading an existing production line, Taizy can provide:

- Professional equipment selection

- Production line planning

- Customized almond processing solutions

Contact us to start your nut business blueprint!