땅콩 포격 기계

| 모델 | TBH-800 |

| 전체 치수(mm) | 1330*750*1570 |

| 순중량(kg) | 160 |

| 생산력 | 600-800kg/h |

| 파손율 | ≤2.0% |

| 피해율 | ≤3.0% |

| 포격율 | ≥98% |

| 힘 | 3kw, 220v, 50hz, 구리 모터 |

| 기능 | 땅콩 껍질 벗기기/껍질 벗기기 |

이제 기술적인 세부 사항에 대해 프로젝트 관리자에게 문의하실 수 있습니다.

우리 땅콩껍질 벗기기 기계는 시간당 200~800kg의 고효율 가공을 제공하여 신뢰할 수 있고 자동화된 땅콩 껍질 벗기기를 보장합니다. 스테인리스 스틸로 만들어져 내구성, 부식 저항성, 안정적인 작동을 제공합니다.

소규모 및 대규모 생산 모두에 적합하며, 독립적으로 작동하거나 땅콩버터 및 로스팅 라인에 통합할 수 있습니다.

이 기계는 높은 커널 무결성을 유지하여 땅콩을 버터, 사탕, 기름, 페이스트리 생산에 이상적이게 하며, 껍질은 바이오매스 연료로 재활용되어 제로 웨이스트 경제를 지원합니다.

효율성, 신뢰성, 지속 가능성을 위해 저희를 선택하세요!

높은 껍질 제거 효율성

땅콩 껍질 벗기기 시리즈는 TBH200, TBH400, TBH800, 6BHD-800D의 네 가지 모델로 구성됩니다. 각 모델은 전기, 가솔린 또는 디젤 엔진과의 호환성을 제공하므로 모든 규모의 농장에 적합합니다.

TBH200 : 효율적인 엔트리 레벨 땅콩 껍질

- TBH200 엔트리 레벨 모델. 효율적인 땅콩 껍질 제거를 위해 설계되었습니다.

- 생산성 향상. 운영 효율성을 향상시킵니다.

- 중소형 농장에 이상적입니다. 신뢰할 수 있고 사용하기 쉬운 포격 솔루션을 제공합니다.

TBH400 : 효과적인 미드 레인지 땅콩 껍질

- TBH400 미드 레인지 모델. 강화 된 기능으로 TBH200에서 업그레이드되었습니다.

- 추가 화면. 더 나은 포격 효율을위한 체질 기능을 향상시킵니다.

- 신뢰할 수있는 성능. 효율적이고 일관된 포격 작업을 보장합니다.

TBH800 : 대규모 생산을위한 고성능 땅콩 껍질

- TBH800 고급 모델. 우리 시리즈에서 가장 진보 된 땅콩 껍질.

- 2 차 포격 기능. 포격 효율과 출력을 향상시킵니다.

- 듀얼 스크린 및 공급 쓰레기통. 처리 용량과 정확도를 향상시킵니다.

- 대규모 농장 및 산업에 이상적입니다. 대량 땅콩 가공을 위해 설계되었습니다.

- 우수한 성능. 광범위한 운영의 최대 효율성을 보장합니다.

6BHD-800D : 다목적이고 효율적인 땅콩 껍질

- 6BHD-800D 다기능 모델. 향상된 기능을 갖춘 다목적 땅콩 껍질.

- 업그레이드 가능한 디자인. 더 나은 안정성과 이동성을 위해 프레임과 큰 타이어를 장착 할 수 있습니다.

- 다양한 응용 프로그램에 적응할 수 있습니다. 다양한 포격 시나리오에 적합합니다.

- 효율적인 성능. 신뢰할 수 있고 고출력 포격 솔루션을 제공합니다.

땅콩 껍질 벗기는 기계는 어떻게 작동하나요?

땅콩 껍질 제거기는 4단계 자동화 과정을 통해 작동하여 효율성과 껍질 제거 정밀도를 극대화하고 견과류 손상을 최소화합니다. 단계별 설명은 다음과 같습니다:

거친-세밀 그리드 드럼 껍질 제거

- 땅콩은 장착 된 회전 드럼에 공급됩니다거친 제출 막대 그리고 a고정형 intaglio 표면.

- 막대와 표면 사이의 롤링 마찰은 커널을 분쇄하지 않고 껍질을 열어줍니다.

공기 흐름을 통한 껍질-견과 분리

- 껍질과 커널의 금이 간 혼합물은 드럼 그리드를 통해 덕트로 떨어집니다.

- a고속 팬 수집을 위해 경량 껍질을 바깥쪽으로 날려 버리고 더 무거운 커널은 다음 단계로 진행됩니다.

중력 기반 정화

- 나머지 혼합물은 a중력 분리기.

- 전체 커널 (밀도)는 즉각적인 포장 또는 추가 처리를 위해 배출 콘센트까지 위로 들어 올립니다.

- 껍질을 벗기거나 부분적으로 껍질을 벗긴 땅콩 (라이터) 재 처리를 위해 엘리베이터로 아래로 떨어 뜨립니다.

폐쇄 루프 재 껍질 제거

- 엘리베이터는 밑바닥 껍질을 벗긴 땅콩을 다시 운반합니다미세 그리드 드럼 두 번째 라운드의 탈취 라운드.

- 이주기는까지 반복됩니다98%+ 포격 효율 최소한의 폐기물을 보장하여 달성됩니다.

상업용 농장 및 가공 공장에 이상적 인이 기계는 원시 땅콩을 비교할 수없는 속도와 신뢰성을 갖춘 고품질 커널로 변형시킵니다.

땅콩 탈곡기 기계의 특징

- 비용 효율적이고 고성능. Peanut Sheller는 경제성을 우수한 품질과 뛰어난 효율성과 결합하여 투자에 큰 가치를 보장합니다.

- 사용자 친화적 인 디자인. 단순한 구조와 잘 고려한 디자인을 통해이 기계는 작동 및 유지 관리가 쉽기 때문에 초보자와 숙련 된 사용자 모두에게 이상적입니다.

- 작고 공간 절약. 이 기계의 작은 크기는 단단한 공간에 맞출 수 있으며 가정 용도 및 소규모 생산 설정 모두에 적합합니다.

- 뛰어난 선체 효율. 헐링 속도가 98%를 초과하면이 기계는 고품질 결과와 최대 출력을 보장합니다.

- 여러 전원 옵션. 전기 모터, 디젤 엔진 또는 가솔린 엔진을 선호하든 운영 요구에 맞는 다양한 전원 옵션을 제공합니다.

- 사용 가능한 사용자 정의. 우리는 기계를 특정 요구 사항에 맞게 조정하여 고유 한 생산 요구에 대한 최적의 성능을 보장하기 위해 강력한 사용자 정의 서비스를 제공합니다.

땅콩 포격기의 매개 변수

| 모델 | 용량 | 힘 | 무게 | 크기 |

| TBH-200 | 200kg/h | 2.2kW 모터, 170F 가솔린 엔진, 6hp 디젤 엔진 | 40kg | 650*560*1000mm |

| TBH-400 | 300-400kg/h | 3kW 모터, 170F 가솔린 엔진, 8hp 디젤 엔진 | / | / |

| TBH-800 | 600-800kg/h | 3kW 모터 또는 170F 가솔린 엔진, 8hp 디젤 엔진 | 160kg | 1330*750*1570mm |

| 6BHD-800B | 600-800kg/h | 2.2-3.0kW 모터 | 160kg | 1330*750*1570mm |

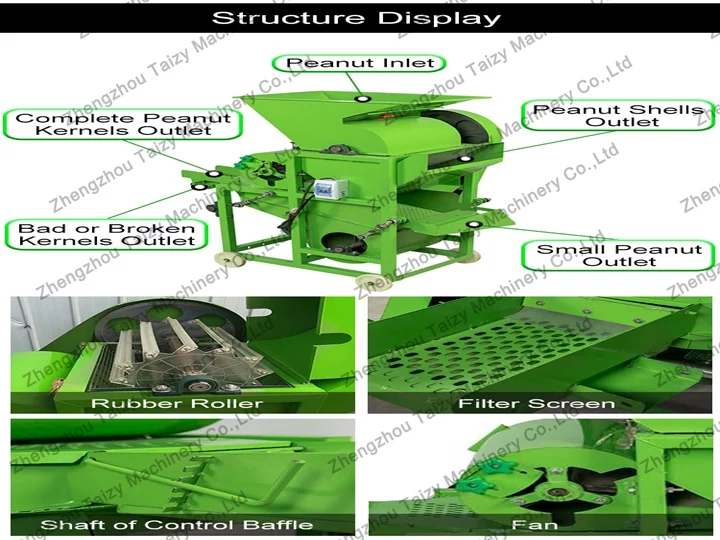

땅콩껍질 제거기의 구조

문의하기

우리의 땅콩 껍질 제거기는 높은 효율성, 높은 껍질 제거율 및 최소한의 견과류 손상을 보장하여 땅콩 가공 비즈니스에 훌륭한 선택이 됩니다. 내구성과 사용 용이성을 위해 설계된 이 기계는 껍질 벗긴 땅콩의 품질을 유지하면서 생산성을 향상시킵니다.

땅콩 껍질 제거기 외에도 땅콩 가공 기계의 다양한 제품을 제공합니다. 여기에는 땅콩 버터 기계, 땅콩 로스팅 기계, 땅콩 오일 프레스 기계가 포함됩니다. 오늘 저희에게 문의하셔서 더 많은 정보와 맞춤형 견적을 받아보세요!