2t Cocoa Paste Production Line

| Material | Stainless steel |

| Capacity | 2t/h |

| Fineness | 100-200mesh |

| Finished product | Cocoa liquor, cocoa mass, cocoa paste |

| Hot-selling countries | Turkey, Denmark, Sweden, Russia, etc. |

You can now ask our project managers for technical details

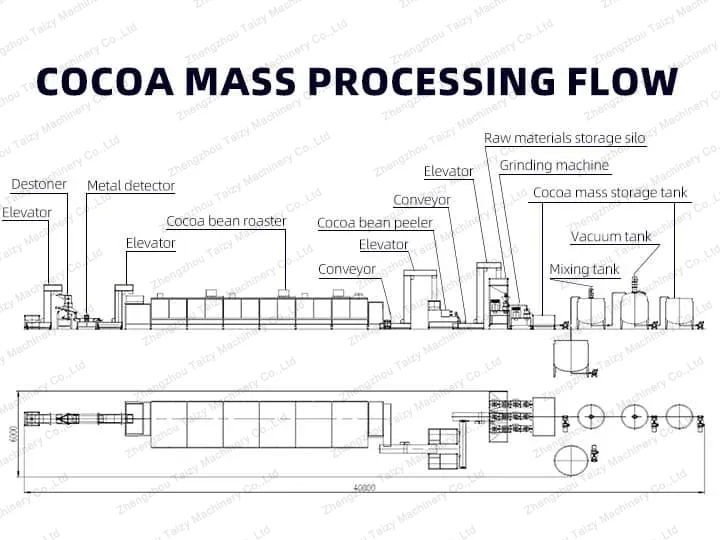

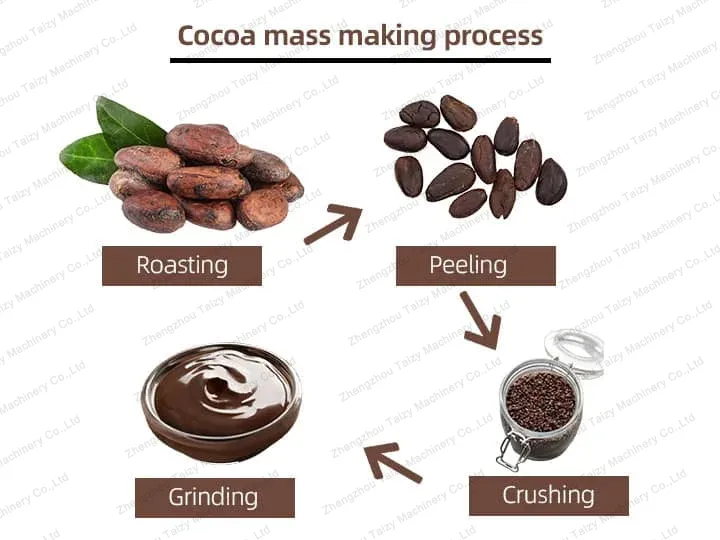

Taizy is now available to produce an Industrial-grade cocoa paste production line for the high-quality cocoa bean processing factory. The whole process includes roasting, peeling, cracking, grinding, and mixing.

Our production line is made of high-quality stainless steel and has an output of up to 2000kg/h. If you have high requirements for the quality of cocoa mass, our production line can produce products with a normal fineness of 100-200 mesh.

Our machines are exported to other regions, including Northern Europe, Asia, and North America. Some high-end handmade chocolate food factories often use it for large-scale cocoa paste processing. If you have any other special requirements, please contact us.

Highlights of fully automatic cocoa paste production line

- Taizy cocoa paste production line encompasses the complete processing flow, including feeding, roasting, peeling, grinding, vacuum degassing, mixing, and storage. The entire process is fully automated with a dedicated control center for easy operation.

- The machines in our production line are constructed of food-grade stainless steel, offering durability and long service life, enabling continuous processing and stable output. Our machines carry CE and SONCAP certifications to ensure their quality.

- Our factory has specialized in nut grinding technology for decades, and our machines produce a uniform and fine cocoa paste with a fineness of up to 200 mesh. If you have a higher level of quality, you can also contact us to gain your ideal production solutions.

Main machines in the cocoa mass production line

Our 2t cocoa paste production line includes such irreplaceable machines: stainless steel feed silos, elevators, a roasting and cooling machine, cocoa bean grinders, a homogenizer, mixing tanks, vacuum degassing tanks, and storage tanks.

Here are some key machines’ detailed introduction:

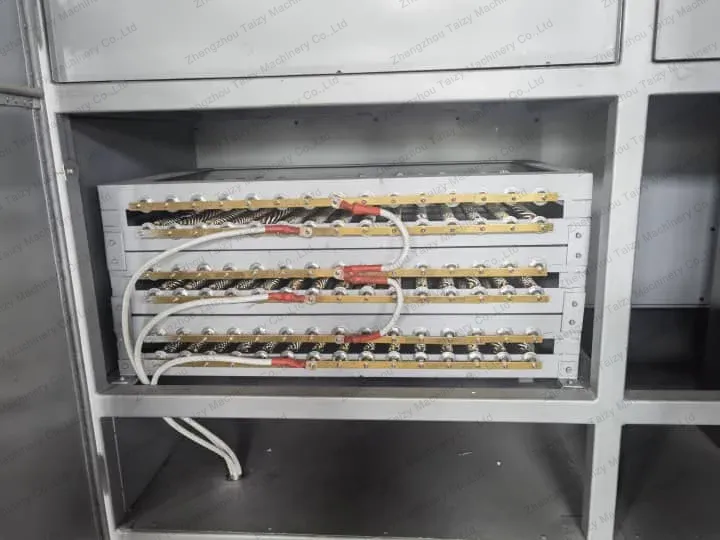

1. Roasting and cooling machine

This roaster is a new type of multifunctional roasting (drying) machine for cocoa, grains, nuts, etc. The temperature is automatically adjusted with various heat source choices, such as electric, gas, and other heating methods.

Its working principle is to use the circulating fan to exchange heat, realize strong airflow baking, and improve baking efficiency. At the back of the equipment, the cooling zone is set to achieve rapid cooling.

| Transmission power | 80KW |

| Heating power | 1150KW |

| Gas consumption | 100-120kg/h |

| Material thickness | 50-60mm |

| Product capacity | 5t/h |

| Dimensions | 40000mm*3000mm*2600mm |

2. Cocoa bean peeling machine

This peeler machine is composed of a peeling roller, a fan, and a gravity sorting part. The gravity sorting part is equipped with three layers of screens, which can effectively screen and remove the peel, and the removal rate can reach >99%.

The waste skins are then collected by a cyclone separator, which not only protects the working environment but also ensures cleaner materials.

| Model | HB-2 |

| Capacity | 1t/h |

| Motor power | 4.4KW |

| Fan power | 2.2KW |

| Voltage | 380V 50HZ |

| Removal rate | >99% |

| Size | 1900mm*1000mm*1400mm |

| Weight | 300kg |

3. Cocoa paste grinder

The grinding head of our grinder machine is made of 9Cr18 stainless steel, and the machine shell is 201 stainless steel. The machine has a very high working efficiency, and for large production lines, it can generally reach 3t-5t/h.

| Model | TZ-220 |

| Voltage | 380V/50HZ |

| Power | 30KW |

| Capacity | 600-900kg/h |

| Weight | 580kg |

| Size | 1080mm*600mm*1350mm |

4. Cocoa mass homogenizer

The cocoa paste homogenizer can fully break up the particles in the cocoa paste and evenly disperse them, making the product taste more delicate and smooth, and even letting the color and gloss be better.

What’s more, the homogenization process keeps cocoa butter and particles evenly mixed, preventing separation or settling, which helps products stay fresh for longer.

| Model | JJ-2/80 |

| Power | 37KW 380V |

| Rated flow | 2000L/h |

| Rated voltage | 80Mpa |

| Using voltage | 65Mpa |

| Size | 1350mm*1200mm*1520mm |

Whole process of cocoa paste making

The complete cocoa paste production process is: roasting→cooling→ peeling→grinding→homogenizating→ mixing→ storing. If you need additional services, such as a cocoa paste filling line or cocoa fruit shelling, we provide the relevant machines.

Note: During mixing, different raw materials can be added and stirred, which is the key step in producing different types of cocoa paste or chocolate paste.

Applications of the cocoa liquor production line

This cocoa paste production line is widely used in the cocoa and chocolate processing industry, ensuring a stable supply of large quantities of fine, uniform cocoa liquor to chocolate factories.

What’s more, the produced cocoa liquor can also be used to produce cocoa butter and cocoa powder. The cocoa mass can be pressed in an oil press machine to separate into cocoa butter and cocoa cake, which is the base of making cocoa powder.

These finished products have a broad market around the world and provide raw material support for a wide range of industries such as confectionery, baking, beverages, dairy products, cosmetics, and pharmaceuticals.

Successful case of cocoa paste production line project

A customer from Türkiye was looking for a fully automatic cocoa mass production line to update his chocolate and confectionery factory. Due to the large production demand and high requirements for the machine, we provided this 2t/h production line.

The initial plan was not smooth. Our customer questioned whether our production line could meet his fineness requirements, so he wanted to add a screening machine for quality inspection. After a round of testing, we found that the fineness can meet the production requirements, but the screening machine actually affected the production efficiency.

After several revisions to the plan, our customer finally determined the investment in the main equipment.

| Machine | Power | Quantity |

| Elevator | 0.75kw | 3 |

| Roaster | / | 1 |

| Discharge sieve | 1.1kw | 1 |

| Nuts peeler | 4.4kw | 2 |

| Dust collector | / | 1 |

| Belt conveyor | 0.37kw | 1 |

| Storage bin | 24kw+100kw | 3 |

| Nuts grinder | 30kw | 6 |

| Holding tank | / | 1 |

| Rotor pump | 4kw + 7.5kw | 4 |

| Mixing tank | 7.5 + 24kw | 3 |

| Vacuum tank | 10 + 24kw | 1 |

Now, this production line has been in operation for half a year, and our customers have given us good feedback. They are planning to add a few more packaging machines to improve the overall automation capabilities of the factory.

Taizy is a professional nuts processing machine and production line manufacturer. We will design the most suitable solution for your company. If you have any requirements and want to ask other questions, please contact us.