Peanut Brittle Making Machine

Peanut Candy Bar Production Line | Peanut Chikki Making Machine

Function: Peanut roasting, peeling, mixing, forming, cutting, and packaging.

Material: Food-grade stainless steel

Application: Peanut brittle, sesame candy, nut energy bars, etc.

Hot-selling countries: Vietnam, Nigeria, India, Bolivia, etc.

The peanut brittle making machine is a fully automatic food processing system specifically designed for producing traditional confectionery products such as peanut candy, peanut brittle, rice crispy treats, sesame candy, and millet cakes.

The complete peanut candy production line integrates functions such as roasting, peeling, sugar boiling, mixing, forming, cutting, and packaging, helping food manufacturers achieve high-volume production, consistent quality, and reduced labor costs.

Advantages of the peanut candy bar production line

- Our peanut brittle making machine automatically completes processes such as roasting, peeling, sugar boiling, mixing, molding, cutting, and packaging, significantly reducing manual labor. While maintaining consistent product quality, it reduces labor costs by 20-50%.

- It allows for flexible and precise speed adjustment throughout the entire process, enabling fine-tuning of production speed based on different candy types, batch sizes, or market demands. This prevents burning or sugar crystallization, maximizing production efficiency.

- Our peanut chikki making machine can customize peanut candy of different sizes and thicknesses according to various packaging requirements and market preferences. This versatility eliminates the need to purchase additional machines to produce different types of products.

- Designed for medium to large-scale production, this peanut brittle making machine has a capacity of 500-800 kg/hour (depending on the configuration), supporting mass production with consistent quality and allowing for long-term continuous operation.

- The whole peanut candy bar production line is made of food-grade stainless steel and features an automated processing design, minimizing human contact to ensure hygiene and compliance with food safety standards.

Applications of the peanut candy making machine

This peanut candy making machine can produce a variety of popular snacks, including peanut candy, peanut brittle, puffed rice candy, sesame candy, millet cakes, and sachima (a type of Chinese pastry).

Its shape and size are adjustable, and the resulting products are of consistent quality and taste, making it ideal for large-scale production of retail snacks.

In addition, we also provide packaging solutions for peanut brittle making machines, offering a complete production line from manufacturing to packaging, effectively improving brand control over quality.

Peanut candy production process

The complete workflow of the peanut brittle making machine is as follows: Peanut roasting → Peanut peeling → Syrup preparation → Material mixing → Forming and cutting → Packaging.

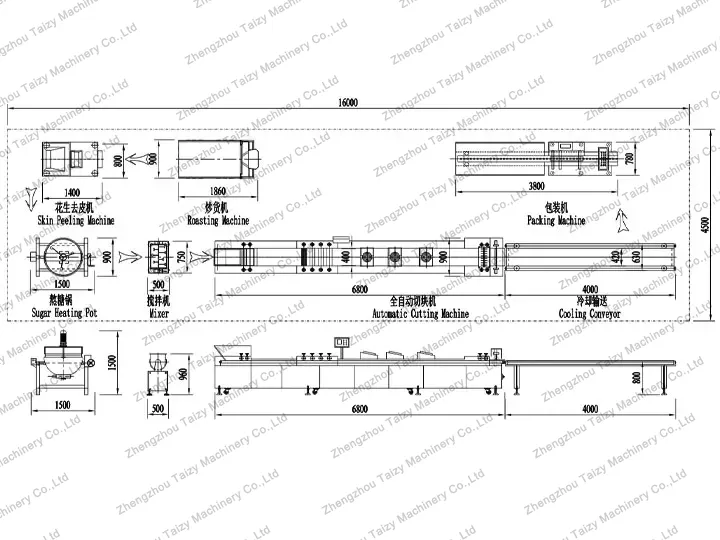

Below is a preliminary layout sketch showing the footprint of such a peanut candy production line. However, this is not a fixed design. Taizy will customize a solution based on your specific needs. Please contact us to get your personalized solution.

1. Peanut roasting

Raw peanuts need to be roasted before proceeding to the following steps. This step not only enhances the aroma and flavor of the peanuts but also makes the dry and crispy shells easier to remove.

A peanut roasting machine is used in this step. This machine comes in two models: electric heating (240-260℃) and gas heating (220-240℃). The machine model and basic configuration are as follows.

| Model | Size | Capacity | Motor | power |

| TZM-1 | 3*1.2*1.7 m | 80-120 kg/h | 1.1 kw | 18 kw |

| TZM-2 | 3*2.2*1.7 m | 180-250 kg/h | 2.2 kw | 35 kw |

| TZM-3 | 3*3.3*1.7 m | 280-350 kg/h | 3.3 kw | 45 kw |

| TZM-4 | 3*4.4*1.7 m | 380-450 kg/h | 4.4 kw | 65 kw |

| TZM-5 | 3*5.5*1.7 m | 500-700 kg/h | 5.5 kw | 75 kw |

2. Peanut peeling

Removing the peanut skins results in a better texture, especially reducing the bitterness from the skins during the later stages of making peanut brittle. Additionally, peeled peanuts have a better appearance, resulting in a more visually appealing finished product.

The peeling process requires manual feeding and can process 200-600 kg of peanuts at a time. The specific parameters of this groundnut peeler are as follows:

| Production capacity | 100-200 kg/h | 400 kg/h | 600 kg/h |

| Power | 0.75 kw | 1.5 kw | 2.61 kw |

| Peeling rate | 98% | 96% | 96% |

| Damage rate | 5-20% | 5-20% | 5-20% |

| Size | 1100*400*1100 mm | 1100*600*1100 mm | 1180*900*1100 mm |

3. Syrup preparation

This step is the preparation process, where sugar is poured into a jacketed kettle and heated to produce a stable syrup. The machine is equipped with a precise temperature control system and can use various heating methods such as natural gas heating, electric heating, and steam heating.

The machine is made of 304 stainless steel, with 314 stainless steel available as an option, and comes in various sizes from 100L to 1000L. The user can set the machine’s temperature, and it is equipped with an electric stirring arm to prevent the syrup from solidifying.

| Model | Diameter | Inner thickness | Outer thickness |

| 100L | 700 mm | 3 mm | 3 mm |

| 200L | 800 mm | 3 mm | 3 mm |

| 300L | 900 mm | 3 mm | 3 mm |

| 400L | 1000 mm | 3 mm | 3 mm |

| 500L | 1100 mm | 4 mm | 3 mm |

| 600L | 1200 mm | 4 mm | 3 mm |

| 800L | 1300 mm | 5 mm | 4 mm |

| 1000L | 1400 mm | 5 mm | 4 mm |

4. Material mixing

Because the solid particles in peanut candy vary in size, a mixer is essential to ensure uniform material distribution and to facilitate the addition of other ingredients that enhance the taste.

The outer shell of this kettle is made of stainless steel, and the inner material is polytetrafluoroethylene, which has the advantages of high temperature resistance, corrosion resistance, non-stick properties, and resistance to deformation.

| Power | 1.1 kw | 2.5 kw |

| Voltage | 380 V 50 Hz | 380 V 50 Hz |

| Dimensions | 700*500*1400 mm | 960*600*1200 mm |

| Mixing capacity | 15 kg/pot | 50 kg/pot |

5. Forming and cutting

The forming, flattening, and cutting are all integrated into a single machine. The liquid mixture, before solidification, is flattened into thin sheets of uniform thickness through a multi-layer flattening structure, and then cut into equally sized peanut candies by pre-set cutters.

This system includes a cooling conveyor, cutter, pressing roller, cooling fan, and flattening device, making it a multi-functional machine that integrates cooling, shaping, and cutting.

| Total power | 380 V/50 HZ 1.5 kw 220 V/50 HZ 2.5 kw |

| Overall dimensions | 8000*1300*1200 mm |

| Machine weight | 1050 kg |

| Production capacity | 50–500 kg/h |

| Finished product weight | 5–300 g (adjustable) |

6. Packaging of the groundnut candy

The product needs to be packaged after cooling. We generally recommend an automatic pillow-type packaging machine to package the product into individual small bags. The packaging form is usually back-sealed, which is the best solution for fast packaging without damaging the product shape.

The machinery configuration of the peanut brittle making machine is not fixed. Our professional sales team will design the most suitable customized solution for you based on your actual production needs and factory size. Contact us to get your exclusive customized solution for peanut candy production!

FAQ about peanut brittle making machine

Is the peanut brittle size and thickness adjustable?

Our molding and cutting system utilizes variable frequency control and multi-stage pressing technology, allowing for flexible adjustment of thickness and cutting dimensions.

What products can the peanut brittle making machine produce?

The peanut brittle making machine is suitable for producing: peanut brittle, puffed rice candy, sesame candy, sachima, etc.

Is the machine fully automatic or semi-automatic?

All the machines are fully automatic, but some of the feeding processes require manual assistance.

What materials are used for the machine?

All parts in contact with food are made of food-grade stainless steel, meeting food safety and hygiene standards.

Is after-sales service and technical support provided?

We provide installation guidance, operation manuals, technical support, and spare parts supply to ensure long-term stable operation of the machine.

Successful case study of a peanut energy bar manufacturing machine in the Philippines

This client is a small snack food manufacturer in the Philippines, primarily producing peanut energy bars and mixed nut brittle for the local market. They operate on a small to medium scale and are looking for a cost-effective, semi-automated solution to replace manual production, cutting, and packaging processes.

Through our collaboration, we successfully built a fully automated production line for peanut candy, significantly increasing production efficiency and improving product quality.

Currently, their product is being supplied across different regions, which are even expanding into overseas markets because its updated packaging and quality standards can satisfy international food export standards.

A semi-automatic peanut brittle making machine has not only helped our customers expand their market but also reduced their production costs, giving them a significant competitive advantage compared to similar products in the local market.

If you have similar problems and want to upgrade your peanut brittle making machine or start your own snack brand, please contact us for the best solutions.