300kg/h Peanut Butter Production Line

| Production capacity | 300kg/h |

| Material | Stainless steel |

| Hot-selling countries | Tanzania, Brazil, Egypt, Vietnam, etc. |

| Main machines | Peanut roaster, peeler, grinder,etc. |

You can now ask our project managers for technical details

Taizy peanut butter production line is a series of equipment used for making peanut butter, encompassing the complete process of roasting, selecting, cooling, peeling, grinding, mixing, degassing, and filling. Its production capacity can achieve 300kg/h.

All our machines are made from food-grade stainless steel, which is durable and has excellent performance. Besides, the peanut butter processing line has the features of high automation, easy operation, and excellent efficiency.

If you are unsure whether the production line is suitable for your factory setup, please feel free to contact us. Taizy will be happy to provide you with the most suitable and cost-effective solution.

Features of Taizy peanut butter production line

- The peanut butter production line adopts international advanced technology, which consists of a feeding elevator, peanut roaster, conveyor, cooling machine, peeling machine, peanut butter making machine, butter pump, and filling machine.

- The production line can produce up to 300kg/h, and the finished peanut butter is delicate. The whole production process is made of food-grade stainless steel, which not only ensures the service life of the machines but also meets international food safety standards.

- Our production line problem solutions are very flexible. We have professional technicians who can provide you with the most suitable production plan. If you have other requirements, we can also customize your exclusive requirements.

What is the production process of peanut butter?

This whole peanut butter production line consists of an elevator, a peanut roasting machine, a cooling machine, a peanut peeling machine, a peanut grinding machine, a mixing tank, a vacuum tank, a storage tank, and a peanut butter filling machine. Every machine has its important functions.

The whole production process of the Taizy peanut butter-making line is as follows:

Raw peanut roasting → selecting → peeling → cooling → grinding → mixing → degassing → peanut butter filling.

Technical data and main machines’ functions of this peanut butter making line

Here are the simple parameters of the main machines in the production line and their detailed functions during the peanut butter process.

| Name | Capacity(kg/h) | Size | Power |

| Peanut roaster | 200kg/h | 1800*2200*1700mm | 2.2kw |

| Delivery belt | 200kg/h | 5000*900*850mm | 1.1kw |

| Peanut peeling machine | 200kg/h | 1900*800*1400mm | 1.85kw |

| Peanut butter machine | 200kg/h | 1100*750*1300mm | 29.5kw |

| Paste pump | 50kg/h*3 | 1500*250*250mm | 1.5kw |

| Peanut cooling machine | 200kg/h | 1000*1000*1700mm | 2.2kw |

| Peanut filling machine | 100-400cans/h | 400*400*1400mm | 1.1kw |

Peanut roaster

The peanut roaster uses hot air or electric heating to evenly heat the peanuts, ripping them, removing moisture, and enhancing their flavor. You can choose electric heating, oil, gas, or coal as the heat source, with a production capacity ranging from 30 to 650 kg/h.

Peanut cooling machine

Rapid cooling of roasted peanuts prevents them from losing their original taste and aroma. Our cooling machines utilize fans to extract hot air for rapid cooling, making them ideal for production lines.

Peanut peeling machine

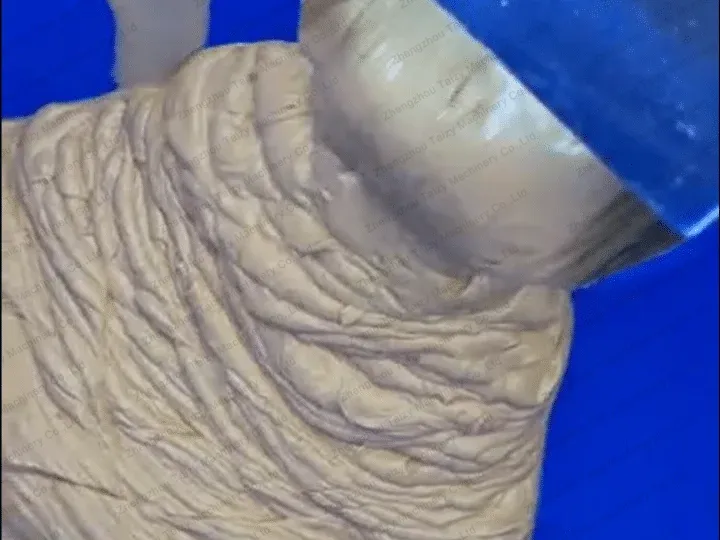

Tiazy peanut peeling machine uses the principle of rubber roller friction or drum friction to quickly and efficiently remove the peanut’s red skin. Its threshing rate can reach 98% with the output of 200-1000kg/h.

Peanut butter machine

We offer different models of peanut butter machines with production ranges from 200 to 5000 kg/h. The finished product is free of fine particles and has a smooth and delicate taste. The machine is made of food-grade stainless steel that can meet most production requirements.

In addition to these machines, mixing tanks, vacuum degassing machines, and peanut butter filling machines are also important components. They complete the production line process and truly provide a full range of production from raw materials to products.

Besides, we provide two types of filling machines: the fully automatic filling machine and the semi-automatic filling machine.

- The fully automatic peanut paste filling machine includes the whole process of filling, capping, vacuum labeling, etc., which can achieve full automation of the production line and save human resources, but its price will be high.

- Semi-automatic peanut butter filling usually only provides a filling function, which can be quantitatively filled, but it requires manual placement of containers. And absolutely, the semi-automatic equipment costs less.

Successful case of peanut butter production line

A customer from Santania customized our semi-automatic peanut butter production line includes a peanut butter grinder, a peanut butter mixing tank, a peanut butter storage tank, and an automatic peanut butter filling machine.

They are a medium-sized farm cooperative that focuses on producing peanuts and processing peanut products for sale. Due to limited space, they consulted our opinions on the purchase of machines and made major investments in key single machines.

Because of the good sales results, they decided to expand production and upgrade the production line to a fully automatic filling machine system. Now their brand is very popular locally, and has entered supermarkets and stores, and the order volume has also increased significantly.

“It is much easier now than before. We are very satisfied with our investment in machine production, and the production efficiency is amazing.”

Taizy is a professional peanut processing machine manufacturer. If you have any problems or want to customize your production line. Please consult us to gain the quota.