Peanut Coating Machine

| Model | TZ-800 |

| Power | 1.5kw |

| Capacity | 100kg/h |

| Weight | 200kg |

| Size | 1000mm×900mm×1100mm |

| Electrical heating power | 6kw |

You can now ask our project managers for technical details

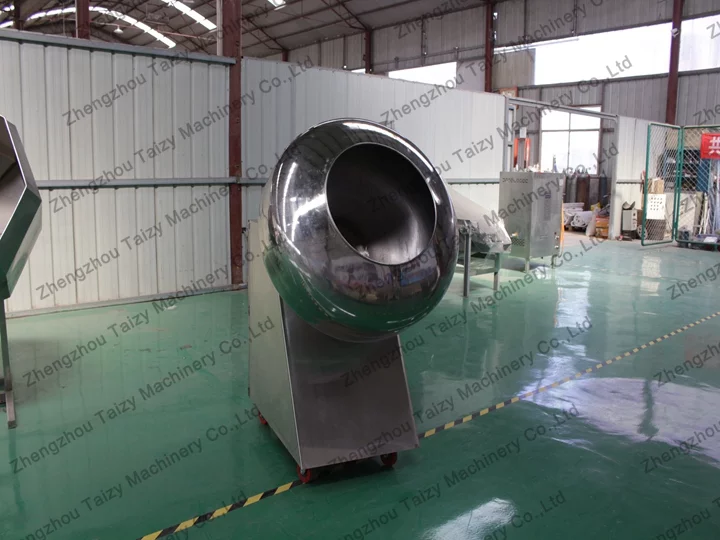

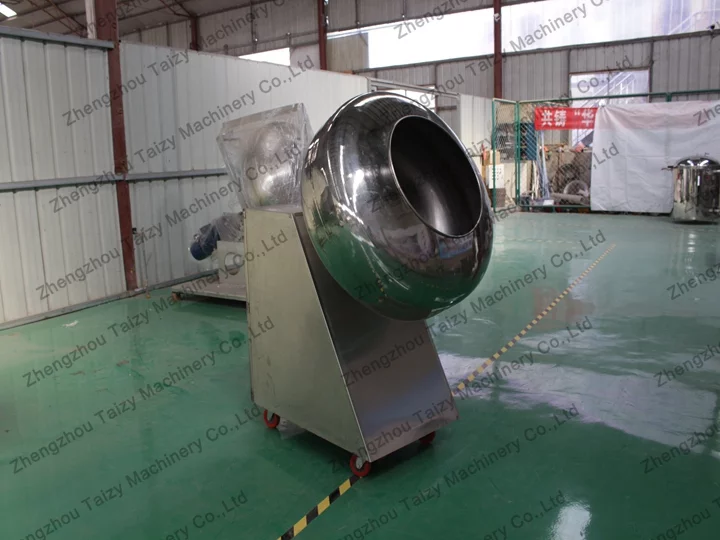

The Peanut Coating Machine is a precision-engineered solution for food manufacturers seeking to elevate snack production with consistent, high-quality flavored coatings.

Designed to automate the entire coating process, this machine ensures uniform distribution of coatings—from chocolate and sugar to savory spices or custom glazes—onto peanuts with exceptional accuracy.

Its robust rotating drum, equipped with adjustable paddles and spray nozzles, gently tumbles peanuts while applying coatings evenly, minimizing waste and maximizing flavor adherence.

With a capacity of 100–120 kg/h, this versatile unit caters to small and medium-scale operations, streamlining workflows while maintaining strict hygiene standards through its food-grade stainless steel construction.

Working principle of a peanut coating machine

- Loading. Peanuts are fed into the machine via a hopper or conveyor system, calibrated to handle capacities up to 100–120 kg/h, ensuring efficient batch processing.

- Drum rotation. The peanuts enter a rotating drum or tumbler, where gentle yet consistent rotation prevents damage while promoting even movement. Adjustable rotation speeds accommodate varying peanut sizes and coating viscosities.

- Coating application. Liquid or powdered coatings (e.g., chocolate, spices, syrup) are applied via precision spray nozzles or dispensers, atomizing liquids into fine mists or evenly dispersing dry mixtures for full surface coverage during tumbling.

- Mixing & adhesion. The tumbling motion ensures peanuts collide, embedding coatings seamlessly. Built-in paddles or baffles intensify agitation, eradicating clumps and guaranteeing uniform layer thickness.

- Airflow & drying. A built-in airflow system delivers targeted air to strip excess coating and speed up drying, ensuring a crisp texture and non-sticky surface while extending shelf life.

- Custom controls. Operators adjust drum speed, temperature, spray intensity, and airflow via an intuitive panel, enabling real-time adjustments to coating thickness, texture, and drying cycles for precise recipe execution.

- Unloading & packaging. Finished coated peanuts exit through a discharge chute, ready for immediate packaging or further processing (e.g., cooling, seasoning). The seamless workflow minimizes downtime and maximizes throughput.

By combining mechanical precision, adjustable automation, and hygienic food-grade construction, the machine guarantees high-quality coated peanuts with minimal waste, catering to both artisanal and industrial-scale snack production demands.

Applications of a peanut coating machine

The peanut coating machine is a versatile asset in the food processing industry, enabling the creation of a wide range of coated snacks tailored to consumer preferences and market demands. Its applications span multiple sectors:

- Flavored snack production

- Sweet variants. Coat peanuts with chocolate, caramel, honey, or sugar for candied treats.

- Savory & spicy options. Apply seasonings like salt, barbecue, chili, or cheese powder to create bold, savory snacks.

- Innovative blends. Experiment with fusion flavors (e.g., honey-sriracha, chocolate-sea salt) to cater to niche markets.

- Confectionery & bakery ingredients

- Supply coated peanuts as toppings for ice cream, desserts, or baked goods (e.g., cookies, cakes).

- Produce chocolate-dipped peanuts for gourmet gift boxes or holiday-themed treats.

- Industrial-scale manufacturing

- Support high-volume production for supermarkets, export markets, or private-label brands with consistent quality.

- Adapt to custom recipes or private formulations, ideal for OEM/ODM partnerships.

- Specialty diets

- Create vegan, gluten-free, or low-sugar coatings to align with dietary trends.

Equipped with food-grade stainless steel construction and adjustable parameters, the machine ensures compliance with hygiene standards while accommodating diverse textures, viscosities, and batch sizes.

From artisanal snack startups to large-scale food processors, it empowers businesses to innovate, scale efficiently, and meet evolving consumer tastes with premium coated peanut products.

Parameters of the peanut coating machine

| Model | TZ-800 | TZ-900 |

| Diameter of pan | Outer diameter:777mm Inner diameter:700mm | 900mm |

| Capacity | 100KG/H | 120KG/H |

| Power | 1.5kw | 1.5kw |

| Dimension | 1000mm×900mm×1100mm | 1100mm×900mm×1500mm |

| Weight | 200kg | 220kg |

| Electrical heating power | 6kw | 8kw |

Automatic coated peanut making machine production line

This integrated line streamlines large-scale coated peanut manufacturing with precision and efficiency. Key stages include:

- Cleaning & sorting – Removes impurities for premium-quality nuts.

- Roasting – Adjustable temperature profiles enhance flavor and texture.

- Coating – Core machine applies chocolate, spices, or glazes via spray nozzles or dispensers, ensuring uniform coverage in a rotating drum.

- Cooling/drying – Stabilizes coatings for crispness and shelf life.

- Packaging – Automated systems portion peanuts into bags or bulk containers.

Designed for confectionery brands and snack manufacturers, this turnkey solution delivers consistent, market-ready products with minimal waste and rapid scalability.

A successful case of groundnut coating machine

In Saudi Arabia, a food processing company enhanced production efficiency and product quality using our advanced peanut coating machine. Its adjustable rotation speed and precise spraying settings ensured uniform coatings, improving peanut taste and appearance.

The machine’s automation and customization features allowed for easy scaling of production while maintaining high standards. This investment boosted operational efficiency and gave the company a market advantage, highlighting the benefits of modern peanut coating technology.

Leave your message!

We are committed to providing our customers with the highest quality groundnut coating solutions. If you have any questions or would like to learn more about our groundnut coating machine, please feel free to leave a message below. Our team will promptly get in touch with you to provide professional assistance and support.

We look forward to collaborating with you to enhance your production efficiency and product quality. Leave your information below and let us help you achieve excellence in your production goals!