Máy bóc vỏ đậu phộng

| Người mẫu | TBH-800 |

| Kích thước tổng thể (mm) | 1330*750*1570 |

| Trọng lượng tịnh (kg) | 160 |

| Năng suất | 600-800kg/giờ |

| Tỷ lệ vỡ | 2,0% |

| Tỷ lệ thiệt hại | .0% |

| Tỷ lệ pháo kích | ≥98% |

| Quyền lực | 3kw, 220v, 50hz, động cơ đồng |

| Chức năng | Bóc vỏ/bóc đậu phộng |

Bây giờ bạn có thể hỏi người quản lý dự án của chúng tôi để biết chi tiết kỹ thuật

Máy bóc vỏ đậu phộng Peanut Shelling Machine của chúng tôi cung cấp quá trình xử lý hiệu quả cao từ 200–800kg mỗi giờ, đảm bảo bóc vỏ đậu phộng tự động và đáng tin cậy. Làm bằng thép không gỉ, nó mang lại độ bền, chống ăn mòn và hoạt động ổn định.

Phù hợp cho cả sản xuất quy mô nhỏ và lớn, nó có thể hoạt động độc lập hoặc tích hợp vào dây chuyền làm bơ đậu phộng và rang.

Máy duy trì độ toàn vẹn của hạt cao, làm cho đậu phộng trở thành nguyên liệu lý tưởng cho sản xuất bơ, kẹo, dầu và bánh ngọt, trong khi vỏ có thể được tái chế thành nhiên liệu sinh khối, hỗ trợ nền kinh tế không chất thải.

Hãy chọn chúng tôi để có hiệu quả, độ tin cậy và tính bền vững!

Máy tách vỏ đậu phộng để bán

Dòng máy bóc vỏ đậu phộng bao gồm bốn mẫu: TBH200, TBH400, TBH800 và 6BHD-800D. Mỗi mô hình đều có khả năng tương thích với động cơ điện, xăng hoặc diesel, đảm bảo phù hợp cho các trang trại thuộc mọi quy mô.

TBH200: Sheller Peanut cấp nhập cảnh hiệu quả

- Mô hình cấp nhập cảnh TBH200. Được thiết kế để loại bỏ vỏ đậu phộng hiệu quả.

- Nâng cao năng suất. Cải thiện hiệu quả hoạt động.

- Lý tưởng cho các trang trại nhỏ đến trung bình. Cung cấp một giải pháp pháo kích đáng tin cậy và dễ sử dụng.

TBH400: Máy xúc xích tầm trung hiệu quả

- Mô hình tầm trung TBH400. Được nâng cấp từ TBH200 với các tính năng nâng cao.

- Màn hình bổ sung. Cải thiện khả năng sàng cho hiệu quả pháo kích tốt hơn.

- Hiệu suất đáng tin cậy. Đảm bảo các hoạt động pháo kích hiệu quả và nhất quán.

TBH800: Vỏ đậu phộng hiệu suất cao để sản xuất quy mô lớn

- Mô hình cao cấp TBH800. Các vỏ đậu phộng tiên tiến nhất trong loạt bài của chúng tôi.

- Chức năng pháo kích thứ cấp. Tăng cường hiệu quả pháo kích và sản lượng.

- Màn hình kép và thùng cho ăn. Cải thiện khả năng xử lý và độ chính xác.

- Lý tưởng cho các trang trại và ngành công nghiệp quy mô lớn. Được thiết kế để chế biến đậu phộng khối lượng lớn.

- Hiệu suất vượt trội. Đảm bảo hiệu quả tối đa cho các hoạt động mở rộng.

6BHD-800D: Vỏ đậu phộng đa năng và hiệu quả

- Mô hình đa chức năng 6BHD-800D. Vỏ đậu phộng đa năng với khả năng nâng cao.

- Thiết kế nâng cấp. Có thể được trang bị khung và lốp lớn để ổn định và di động tốt hơn.

- Thích nghi cho các ứng dụng khác nhau. Thích hợp cho các kịch bản pháo kích khác nhau.

- Hiệu suất hiệu quả. Cung cấp một giải pháp pháo kích đáng tin cậy và đầu ra cao.

Máy bóc vỏ đậu phộng hoạt động như thế nào?

Máy tách vỏ đậu phộng hoạt động qua một quá trình tự động bốn giai đoạn được thiết kế để tối đa hóa hiệu quả và độ chính xác tách vỏ trong khi giảm thiểu hư hại hạt. Dưới đây là phần từng bước:

Máy tách vỏ lúa thô-tinh

- Đậu phộng được đưa vào trống xoay được trang bịthanh hồ sơ thô và aĐã sửa lỗi bề mặt intaglio.

- Ma sát lăn giữa các thanh và bề mặt làm nứt vỏ mở mà không nghiền nát hạt nhân.

Phân tách vỏ-hạt bằng luồng khí

- Hỗn hợp bị nứt của vỏ và hạt nhân rơi qua lưới trống thành một ống dẫn.

- Aquạt tốc độ cao thổi những chiếc vỏ nhẹ ra ngoài để thu thập, trong khi hạt nhân nặng hơn tiến tới giai đoạn tiếp theo.

Làm sạch dựa trên trọng lực

- Hỗn hợp còn lại vàophân tách trọng lực.

- Hạt nhân đầy đủ (dày đặc hơn) được nâng lên đến cửa hàng xả để đóng gói ngay lập tức hoặc xử lý thêm.

- Đậu phộng không được vỏ hoặc được bóc vỏ một phần (nhẹ hơn) thả xuống một thang máy để xử lý lại.

Tách lại vòng kín

- Thang máy vận chuyển đậu phộng được đặt dướitrống lưới tốt Đối với một vòng thứ cấp của việc mất hiệu lực.

- Chu kỳ này lặp lại cho đến khi98%+ hiệu quả pháo kích đạt được, đảm bảo chất thải tối thiểu.

Lý tưởng cho các trang trại thương mại và các nhà máy chế biến, máy này biến đậu phộng thô thành hạt nhân chất lượng cao với tốc độ và độ tin cậy chưa từng có.

Đặc điểm của máy bóc vỏ đậu phộng

- Hiệu quả chi phí và hiệu suất cao. Peanut Sheller kết hợp khả năng chi trả với chất lượng tuyệt vời và hiệu quả đặc biệt, đảm bảo giá trị lớn cho khoản đầu tư của bạn.

- Thiết kế thân thiện với người dùng. Với cấu trúc đơn giản và thiết kế được suy nghĩ kỹ lưỡng, máy rất dễ vận hành và bảo trì, làm cho nó trở nên lý tưởng cho cả người mới bắt đầu và người dùng có kinh nghiệm.

- Nhỏ gọn và tiết kiệm không gian. Kích thước nhỏ của máy cho phép nó phù hợp với không gian chặt chẽ, hoàn hảo cho cả việc sử dụng nhà và thiết lập sản xuất nhỏ hơn.

- Hiệu quả vỏ đặc biệt. Với tốc độ thân tàu vượt quá 98%, máy này đảm bảo kết quả chất lượng cao và đầu ra tối đa hóa.

- Nhiều tùy chọn năng lượng. Cho dù bạn thích động cơ điện, động cơ diesel hoặc động cơ xăng, chúng tôi cung cấp một loạt các tùy chọn năng lượng phù hợp với nhu cầu hoạt động của bạn.

- Tùy chỉnh có sẵn. Chúng tôi cung cấp các dịch vụ tùy biến mạnh mẽ để điều chỉnh máy theo yêu cầu cụ thể của bạn, đảm bảo hiệu suất tối ưu cho nhu cầu sản xuất độc đáo của bạn.

Các thông số của máy bắn pháo đậu phộng

| Người mẫu | Dung tích | Quyền lực | Cân nặng | Kích cỡ |

| TBH-200 | 200kg/giờ | Động cơ 2.2kW, động cơ xăng 170F, động cơ diesel 6hp | 40kg | 650*560*1000mm |

| TBH-400 | 300-400kg/giờ | Động cơ 3kW, động cơ xăng 170F, động cơ diesel 8hp | / | / |

| TBH-800 | 600-800kg/giờ | Động cơ 3kW HOẶC động cơ xăng 170F, động cơ diesel 8hp | 160kg | 1330*750*1570mm |

| 6BHD-800B | 600-800kg/giờ | Động cơ 2,2-3,0kW | 160kg | 1330*750*1570mm |

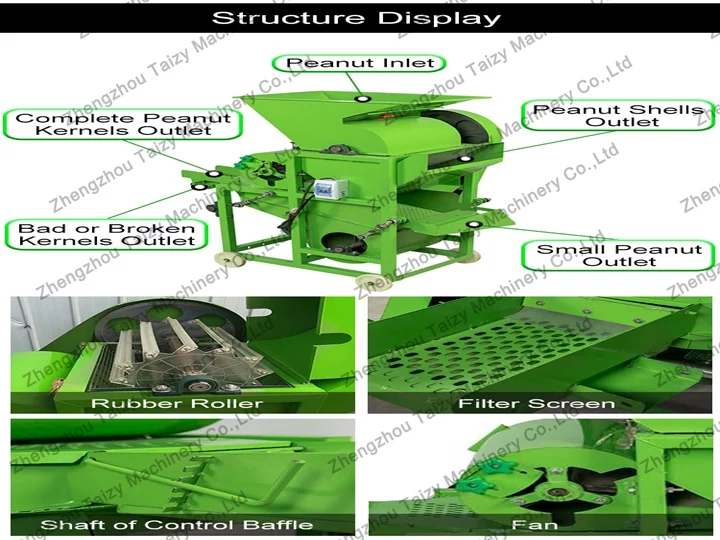

Cấu tạo của máy bóc vỏ đậu phộng

Liên hệ với chúng tôi

Máy tách vỏ đậu phộng của chúng tôi đảm bảo hiệu quả cao, tỉ lệ bóc vỏ cao và hư hại hạt tối thiểu, là lựa chọn tuyệt vời cho các doanh nghiệp chế biến đậu phộng. Được thiết kế cho độ bền và dễ sử dụng, máy này tăng năng suất đồng thời giữ chất lượng đậu phộng đã bóc.

Ngoài máy tách vỏ đậu phộng, chúng tôi còn cung cấp nhiều loại máy chế biến đậu phộng, bao gồm máy làm bơ đậu phộng, máy rang đậu phộng, và máy ép dầu đậu phộng. Liên hệ với chúng tôi ngay hôm nay để biết thêm chi tiết và nhận báo giá tùy chỉnh!