پستہ چھلکا اتارنے والی مشین

پستہ خول ہٹانے والی مشین | پستہ ہلر مشین

گنجائش: 120kg/h

شیلنگ ریٹ: 95٪

ٹوٹنے کی شرح: 8٪

مواد: اسٹین لیس سٹیل

پاور: 2.6kw

والٹیج: 380V / 50Hz

وزن: 260kg

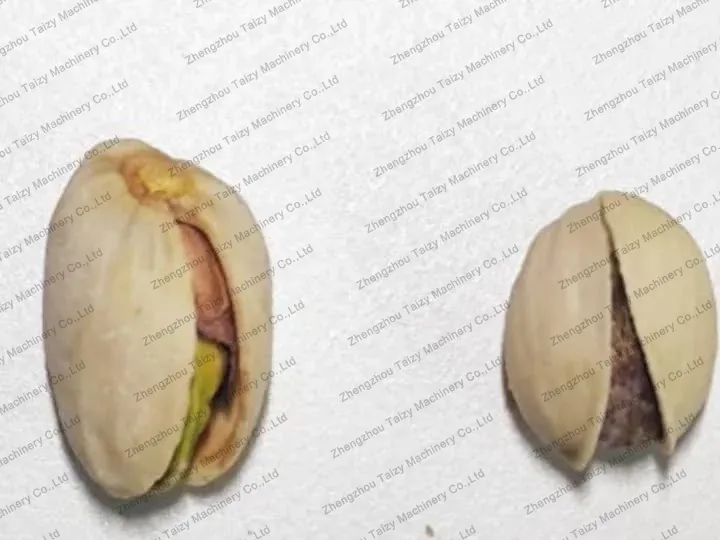

پستہ شیلنگ مشین سخت بیرونی خول کو مؤثر طریقے سے ہٹانے کے لیے ڈیزائن کی گئی ہے جبکہ مغز کی سالمیت برقرار رکھی جاتی ہے۔ 95٪ تک کی اعلیٰ شیلنگ ریٹ اور 8٪ سے کم ٹوٹنے کی شرح کے ساتھ، یہ فی گھنٹہ 120 کلو تک خام پستہ پروسیس کر سکتی ہے۔

پستہ کی پروسیسنگ کے لیے Taizy پستہ ہلنگ مشین کیوں استعمال کریں؟

- پستہ شیلنگ مشین اعلیٰ شیلنگ کارکردگی اور استحکام کا دعوی کرتی ہے، 95٪ تک کی شیلنگ ریٹ حاصل کرتی ہے۔

- Taizy پستہ ہلر مشین صرف 8٪ ٹوٹے ہوئے مغز پیدا کرتی ہے۔

- یہ مشین 2.6 kW ایڈجسٹ ایبل اسپیڈ موٹر سے لیس ہے، جو مختلف سائز کے پستہ شیلنگ کے لیے موزوں ہے۔

- مضبوط سٹین لیس سٹیل سے بنی، مشین نہ صرف سنکنرن مزاحم ہے بلکہ حفظانِ صحت کے لحاظ سے بھی آسان صفائی کے قابل ہے۔

پستہ خول ہٹانے والی مشین کیسے ہوتی ہے کام؟

پستہ شیلنگ مشین ایک قابلِ کنٹرول میکانکی خول توڑنے والے نظام کا استعمال کرتی ہے۔ اس کا ورک فلو یہ ہے: فیڈنگ → شیل توڑنا → اسکریننگ۔

ایک ایڈجسٹ ایبل اسپیڈ موٹر اندرونی رولرز یا خول توڑنے والے اجزاء کو چلاتی ہے تاکہ رگڑ اور دباؤ کے ذریعے خول توڑا جا سکے بغیر مغز کو نقصان پہنچائے۔

وائبریٹنگ اسکریننگ سسٹم پھر خول کو مغز سے جدا کرتا ہے اور انہیں مختلف آؤٹ لیٹس سے خارج کرتا ہے۔ (حتمی جمع شدہ مغز میں کچھ خول شامل ہوں گے۔ ہم مزید اسکریننگ کے لیے چھلنی استعمال کرنے کی سفارش کرتے ہیں۔)

صفائی شدہ پستہ کے مغز پھر مزید پروسیس کیے جا سکتے ہیں، جیسے چھیلنا یا پیسنا۔ یہ میکانکی شیلنگ عمل اعلیٰ شیل کھلنے کی شرح اور کم مغز نقصان کو یقینی بناتا ہے۔

پستہ شیلنگ مشین کے تکنیکی پیرامیٹرز

| طاقت | 2.6kw |

| Voltage | 380V / 50Hz |

| صلاحیت | 120کلوگرام/گھنٹہ |

| شیلنگ ریٹ | 95% |

| ٹوٹا ہوا ریٹ | 8% |

| Material | Stainless steel |

| مشین کا سائز | 3.2 × 1 × 1.9m |

| پیکنگ سائز | 3.7 × 1.1 × 2m |

| وزن | تقریباً 260kg |

پستہ شیلنگ مشین کے اطلاقات

یہ مشین گری دار اور سنیک پیداوار لائنوں اور بیکنگ اور کنفیکشنری اجزاء کی تیاری میں بڑے پیمانے پر استعمال ہوتی ہے۔

شیل کیے گئے پستے کو ٹکڑوں، پٹّیوں میں کاٹا جا سکتا ہے، پاؤڈر میں پیسا جا سکتا ہے، یا پیسٹ بنایا جا سکتا ہے۔ اس کا عمدہ رنگ اور منفرد خوشبو اسے میٹھائیوں اور بیکنگ میں بہت مطلوب بناتی ہے۔

دیگر مطابقت پذیر گری دار مشینیں

یہ شیلنگ مشین درج ذیل آلات کے ساتھ مل کر استعمال کی جا سکتی ہے تاکہ دیگر زیادہ قدر والے گری دار مصنوعات تیار کی جا سکیں:

گری دار میشین برائے درجہ بندی : درجہ بندی اور نجاستیں ہٹانے کے لیے استعمال ہوتی ہے

- یہ خول کے باقیات ہٹانے کے لیے استعمال ہوتی ہے۔

- درجہ بندی دانوں کی پاکیزگی کو نمایاں طور پر بہتر بنا سکتی ہے۔

پستہ چھیلنے والی مشین : پستہ کے مغز کی سرخ بیرونی جلد ہٹاتی ہے

- چھیلنے کے بعد، یہ اعلیٰ درجے کی مارکیٹ کے لیے روشن سبز مغز پیدا کرتی ہے۔

- یہ مزید پروسیسنگ سے پہلے کھاراپن دور کر سکتی ہے، جس سے مصنوعات کا معیار بہتر ہوتا ہے۔

پستہ گرائنڈر : پستہ مکھن تیار کرتی ہے

- یہ بیکنگ، آئس کریم، اور کنفیکشنری صنعتوں میں استعمال ہوتی ہے۔

- انہیں پستہ کے مغز کے ساتھ ملا کر لذیذ نٹ بٹر بنایا جا سکتا ہے۔

پستہ اسٹرپ کاٹنے والی مشین : پستہ کے مغز کو پٹّیوں میں کاٹتی ہے

- پستہ کی پٹّیاں اعلیٰ درجے کی روٹیوں یا میٹھائیوں کے ساتھ پیش کی جاتی ہیں۔

- وہ کھانے کے بافت اور ظاہری شکل کو مالا مال کر سکتے ہیں۔

چھوٹے پیمانے کی پستہ شیلنگ پروڈکشن لائن

ایک عام چھوٹے پیمانے کی پستہ پروسیسنگ پروڈکشن لائن میں شامل ہوتے ہیں: ایک فیڈنگ لفٹر، ایک پستہ شیلنگ مشین، اور ایک وائبریٹنگ اسکرین۔ یہ بنیادی ترین آلات ہیں جو پستہ شیلنگ اور اسکریننگ جیسے کاموں کو مؤثر طریقے سے سنبھالتے ہیں۔

اگر آپ کو دیگر پیشہ ورانہ پروسیسنگ کی ضروریات ہیں تو آپ اپنی مصنوعات کی ضروریات یا مطلوبہ نتائج بتا سکتے ہیں، اور ہماری پیشہ ور ٹیم آپ کے لیے سب سے موزوں حل ڈیزائن کرے گی۔

قابلِ اعتماد پستہ شیلنگ مشین بنانے والے کا انتخاب کیسے کریں؟

قابلِ اعتماد پستہ شیلنگ مشین بنانے والے کا انتخاب کرتے وقت درج ذیل عوامل پر غور کریں:

- پیداوار کا تجربہ: گری دار پروسیسنگ آلات بنانے میں برسوں کے تجربے والے سپلائر زیادہ پیشہ ور ہوتے ہیں۔

- حقیقی صارف کے کیسز: تنصیب کے کیسز اور صارف کی رائے بہتر فیڈبیک فراہم کرتی ہے۔

- تکنیکی معاونت: یقینی بنائیں کہ صنعت کار تنصیب کی رہنمائی، آپریشن کی تربیت وغیرہ فراہم کرتا ہو۔

- معیار کی تصدیق: چیک کریں کہ آیا مشین فوڈ سیفٹی اور برآمدی معیارات پر پورا اترتی ہے۔

مزید برآں، ایک قابلِ اعتماد صنعت کار نہ صرف آلات فراہم کرتا ہے بلکہ مکمل پروسیسنگ حل بھی دیتا ہے۔ لہٰذا خریدار کے لیے ایک معتبر شراکت دار تلاش کرنا متعدد پہلوؤں سے محتاط جانچ کا متقاضی ہے۔

Taizy Machinery، ایک فیکٹری جو دہائیوں سے گری دار بنانے والے آلات میں مہارت رکھتی ہے، عالمی کیس اسٹڈیز اور وسیع درآمد/برآمد کا تجربہ رکھتی ہے۔ ہم اپنے گاہکوں کو اعلیٰ معیار، لاگت کے موثر مشینیں اور جامع خدمات فراہم کرنے کا ہدف رکھتے ہیں۔

اگر آپ کو ہماری پستہ ہلر مشین کے بارے میں کوئی الجھن ہے تو مزید تفصیلات حاصل کرنے کے لیے براہِ کرم ہم سے رابطہ کریں۔