海地安装花生涂层机

最近,我们向海地的一家食品加工公司销售了一台花生包衣机。该公司以其各种花生制品而闻名,在当地市场占有重要份额。

面对不断增长的需求,客户需要一台能够提高生产效率同时保持高产品质量的机器。

在对他们的需求进行全面评估后,我们提供了量身定制的解决方案,显着提高了他们的输出能力。

客户的需求与挑战

在咨询过程中,客户强调了几个关键挑战。

- 提高生产能力。随着产品需求的增长,该公司需要一台能够加工大量花生并同时确保涂层均匀的机器。

- 各种涂层。该公司生产具有不同涂层的花生,包括糖浆、巧克力和香料混合物,因此机器需要足够的多功能性来处理多种类型的涂层。

- 自动化和效率。高劳动力成本促使客户寻求更加自动化的解决方案,以减少人工干预并提高效率。

我们的解决方案

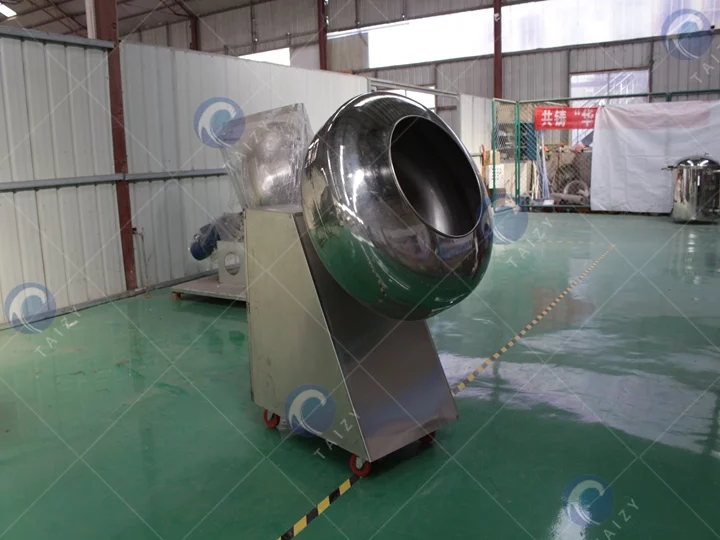

为了满足这些需求,我们推荐了我们先进的花生包衣机。

该机配备转鼓、涂层分配系统和气流控制机构,为花生涂层提供高效的解决方案。

成功的关键因素

此次合作的成功可归因于以下几点。

- 灵活的性能。该机器能够处理各种涂层和批量大小,完美匹配客户多样化的产品系列。

- 自动化。高水平的自动化减少了对体力劳动的需求,降低了成本并提高了生产速度。

- 卓越的产品品质. 机器高效的涂层系统确保每一颗花生都均匀涂覆,符合市场的高品质标准。

结论

花生涂衣机的成功部署,显着提升了客户的生产能力和产品质量。

随着其产品需求的持续增长,我们期待未来能与他们进行更多合作,为他们提供更多的坚果加工机械,以帮助他们扩大产品线并进一步优化生产流程。