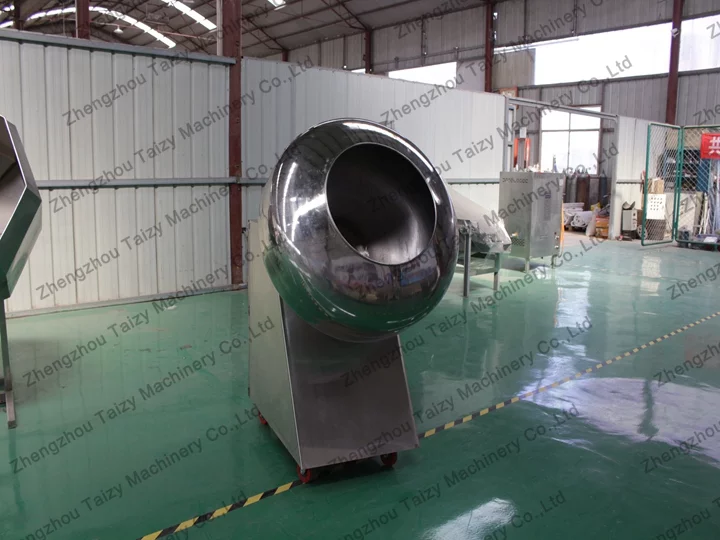

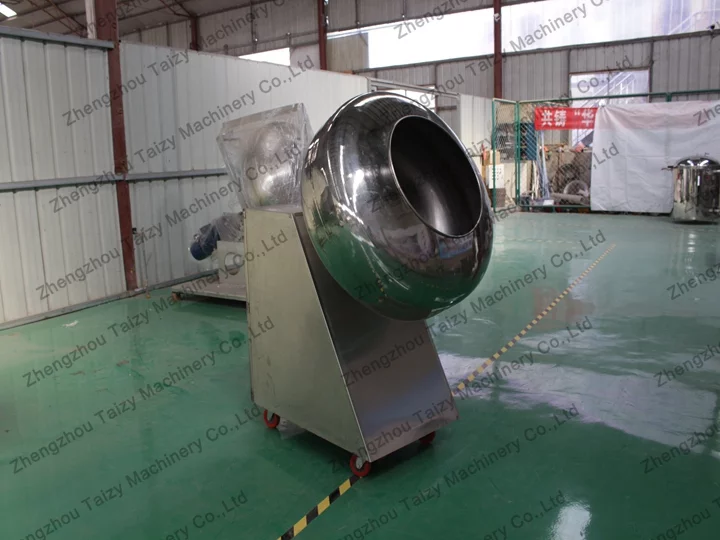

花生裹衣机

| 模型 | TZ-800 |

| 力量 | 1.5千瓦 |

| 容量 | 100公斤/小时 |

| 重量 | 200公斤 |

| 尺寸 | 1000mm×900mm×1100mm |

| 电加热能力 | 6kw |

您现在可以向我们的项目经理询问技术细节

The Peanut Coating Machine is a precision-engineered solution for food manufacturers seeking to elevate snack production with consistent, high-quality flavored coatings.

该机器旨在自动化整个涂料工艺,可确保涂料的均匀分布(从巧克力和糖到咸味香料或定制的釉料),其精度具有出色的精度。

其坚固的旋转鼓,配备可调节的桨和喷嘴,在均匀地涂上涂料时轻轻滚动花生,最大程度地减少浪费并最大化风味的粘附。

With a capacity of 100–120 kg/h, this versatile unit caters to small and medium-scale operations, streamlining workflows while maintaining strict hygiene standards through its food-grade stainless steel construction.

花生涂衣机的工作原理

- 加载中。花生通过料斗或传送带系统馈入机器,校准以处理能力至100–120 kg/h,确保有效的批处理处理。

- 鼓旋转。花生进入一个旋转的鼓或不倒翁,在促进运动时,温和的一致旋转会阻止损坏。可调节的旋转速度可容纳不同的花生尺寸和涂料粘度。

- 涂料应用。液体或粉末涂料(例如,巧克力,香料,糖浆)是通过精密喷雾喷嘴或分配器应用的,将液体雾化成细雾或均匀分散干燥的混合物,以使其在翻滚过程中进行全面的表面覆盖。

- 混合和粘附。翻滚运动确保花生碰撞,无缝嵌入涂料。内置的桨或挡板加剧了搅拌,消除团块并保证均匀的层厚度。

- 气流和干燥。内置的气流系统可提供有针对性的空气,以剥离多余的涂层并加速干燥,从而确保质地清晰,并在延长保质期的同时。

- 自定义控件。操作员通过直观的面板调节鼓速度,温度,喷雾强度和气流,从而实时调整涂层厚度,质地和干燥周期,以进行精确的配方执行。

- 卸载和包装。完成的涂层花生通过排放斜槽退出,准备立即包装或进一步加工(例如冷却,调味)。无缝的工作流程最大程度地减少停机时间并最大化吞吐量。

通过结合机械精度,可调节的自动化和卫生食品级结构,该机器可以保证具有最小废物的高质量涂层花生,并满足手工和工业规模的零食生产需求。

花生裹衣机的应用

花生涂料机是食品加工行业的一种多功能资产,可以创建针对消费者偏好和市场需求量身定制的各种涂层小吃。它的应用程序涵盖了多个部门:

- 调味零食生产

- 甜美的变体。用巧克力,焦糖,蜂蜜或糖涂上花生,用于蜜饯。

- 咸味和辛辣的选择。涂抹盐,烧烤,辣椒或奶酪粉等调味料,制作大胆的咸味小吃。

- 创新的混合物。尝试融合口味(例如蜂蜜 - 奶油,巧克力盐),以适应利基市场。

- 糖果和面包店成分

- 提供涂层的花生作为冰淇淋,甜点或烘焙食品的浇头(例如饼干,蛋糕)。

- 生产蘸巧克力的花生,用于美食礼品盒或以节日为主题的零食。

- 工业规模的制造

- 为超市,出口市场或私人标签品牌提供一致的质量,为大批量生产提供高批量生产。

- 适应自定义食谱或私人配方,非常适合OEM/ODM合作伙伴关系。

- 专业饮食

- 创建纯素食,无麸质或低糖涂料,以与饮食趋势保持一致。

Equipped with food-grade stainless steel construction and adjustable parameters, the machine ensures compliance with hygiene standards while accommodating diverse textures, viscosities, and batch sizes.

从手工零食初创企业到大型食品加工机,都可以通过高级涂层花生产品来创新,有效地进行创新,有效地扩展和满足不断发展的消费者口味。

花生裹衣机参数

| 模型 | TZ-800 | TZ-900 |

| 锅直径 | 外径:777mm 内径:700mm | 900毫米 |

| 容量 | 100公斤/小时 | 120kg/h |

| 力量 | 1.5千瓦 | 1.5千瓦 |

| 方面 | 1000mm×900mm×1100mm | 1100mm×900mm×1500mm |

| 重量 | 200公斤 | 220公斤 |

| 电加热能力 | 6kw | 8kW |

全自动裹衣花生仁生产线

该综合线条以精确和效率简化了大规模涂层花生制造。关键阶段包括:

- 清洁和分类 - 清除高级质量坚果的杂质。

- 烘烤 - 可调节的温度曲线可增强风味和质地。

- 涂层 - 核心机器通过喷嘴或分配器应用巧克力,香料或釉料,以确保旋转的滚筒中均匀的覆盖范围。

- 冷却/干燥 - 稳定涂料以酥脆和保质期。

- 包装 - 自动化系统部分花生成袋或散装容器。

该交钥匙解决方案专为糖果品牌和零食制造商而设计,可提供一致的,可提供市场的产品,具有最小的浪费和快速可扩展性。

花生涂衣机成功案例

在沙特阿拉伯,一家食品加工公司使用高级花生涂料机,提高了生产效率和产品质量。其可调节的旋转速度和精确的喷涂设置可确保均匀的涂料,从而改善了花生的味道和外观。

该机器的自动化和定制化功能使得在保持高标准的同时轻松实现生产规模的扩大。此次投资提高了运营效率并为公司带来了市场优势,突显了现代花生裹衣技术的优势。

留下您的留言!

We are committed to providing our customers with the highest quality groundnut coating solutions. If you have any questions or would like to learn more about our groundnut coating machine, please feel free to leave a message below. Our team will promptly get in touch with you to provide professional assistance and support.

我们期待与您合作,提高您的生产效率和产品质量。请在下面留下您的信息,让我们帮助您实现卓越的生产目标!