High-Efficiency Wet Type Peanut & Almond Skin Peeler Machine

| Model | ST-8, ST-11 |

| Power | 1.5 kW |

| Capacity | 150-220 kg/h |

| Peeling rate | 96% |

| Half kernel rate | ≤ 6% |

You can now ask our project managers for technical details

The almond skin peeler machine is a professional wet peeling equipment specifically designed to remove the skins of soaked almonds, peanuts, soybeans, and broad beans.

It utilizes a rubber roller friction peeling principle, achieving a peeling efficiency of 150-220 kg/hour and a peeling rate of 96%. The peeled product has a 6% rate of broken kernels, making it a key machine in the pre-processing of peanuts, almonds, and other nuts.

Highlight of the almond peeling machine

Compared to traditional manual peeling or dry peeling equipment, the almond peeling machine offers significant advantages:

- High peeling rate of up to 96% meets the needs of industrial production.

- A low breakage rate (half-kernel rate ≤6%) of the almond peeling machine ensures that the kernels remain relatively intact.

- Its peeling process does not damage the protein structure, preserving the natural color and taste of the kernels.

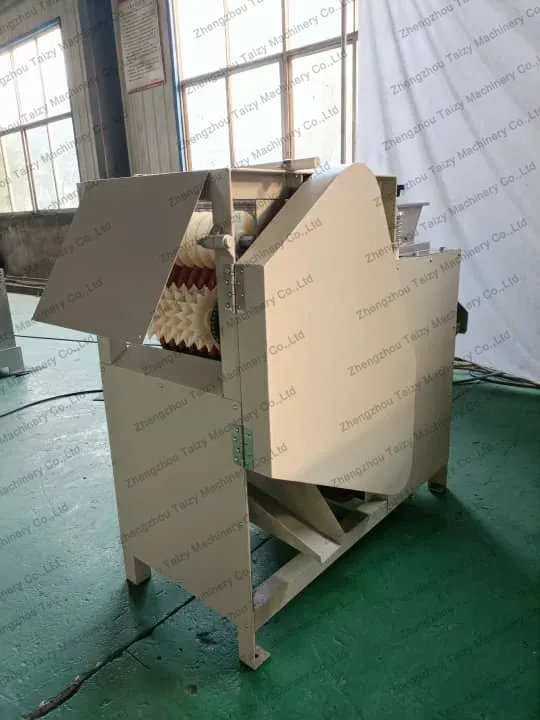

- The almond peeling machine features a compact structure, occupying a small footprint and making it easy to install.

- Taizy almond skin peeler machine is made of durable carbon steel (304 stainless steel material is also available for customization).

Almond peeling machine working steps

The almond peeling machine utilizes a wet friction peeling principle, which involves peeling soaked nuts or legumes. This process ensures high peeling efficiency while minimizing kernel damage. Below are the steps and working principle:

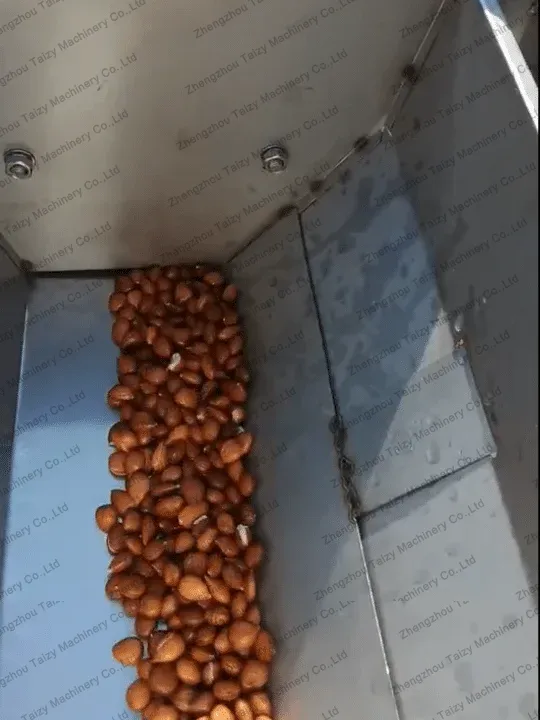

Step 1: Almonds or peanuts are soaked in warm water to soften the red outer skin.

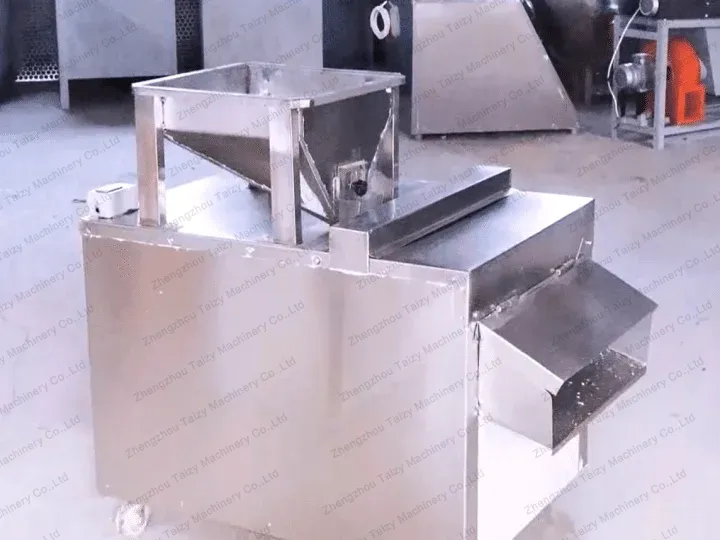

Step 2: Feed the soaked raw materials into the hopper of the almond skin peeler machine.

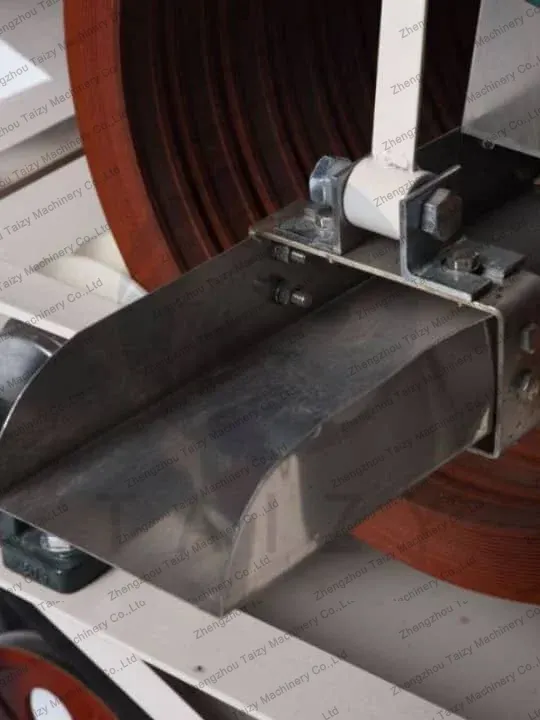

Step 3: The raw materials pass through a feeding screen into the rubber peeling rollers.

Step 4: During the rotation of the rollers, friction effectively removes the outer skin. And the kernels and outer skins are automatically separated upon discharge.

Step 5: The clean white kernels are collected, while the outer skins are discharged separately.

Parameters of the almond skin peeler machine

| Model | ST-11 | ST-8 |

| Power | 1.5 kW | 1.5 kW |

| Capacity | 200–220 kg/h | 150–160 kg/h |

| Peeling rate | 96% | 96% |

| Half kernel rate | ≤ 6% | ≤ 6% |

| Machine size | 1100 × 760 × 1050 mm | 1160 × 760 × 1100 mm |

When selecting an almond peeling machine, consider its processing capacity, the type of raw materials to be processed, and the available factory space and power supply.

Additionally, we offer customized machine services. Whether to change the machine materials or to adjust the voltage, we can produce the machine according to your specific needs.

What materials can be peeled by the almond skin peeler machine?

The almond skin peeler machine is suitable for removing the outer skin (red skin or seed coat) of various nuts and legumes after soaking. It can efficiently remove the outer skin of the following materials:

- Almonds – removing the brown outer skin for subsequent food processing

- Peanuts – removing the red outer skin (peanut seed coat)

- Soybeans – removing the soybean seed coat

- Broad beans – removing the outer skin

Almond kernels are an ideal ingredient for various food processing applications. They are widely used in the production of almond milk and almond beverages, as well as in baking products such as almond flakes and crushed almonds.

Shelled peanuts can be used to make fried peanuts, peanut butter, peanut drinks, and other peanut-based snack products such as peanut candy.

Compared to unpeeled raw materials, wet-peeled almonds and peanuts have a better taste and texture, significantly improve downstream processing efficiency, and effectively remove b

Common nut machine combinations

Almond slicing process:

The almond slicing process requires two machines: a wet-type almond skin peeler machine and an almond slicing machine. The combined use of these two machines significantly reduces almond breakage during slicing, improving product quality and production efficiency.

Almond paste production:

This process requires at least an almond peeling machine and an almond grinding machine. Removing the almond skins effectively reduces bitterness, resulting in a sweeter and smoother almond paste.

Therefore, an almond peeling machine is not just a simple pre-processing machine, but one that can directly affect the quality of the final product. If you plan to invest in a production line for almonds or peanuts, our technical team will provide you with a free customized solution to meet your specific needs.

Common problems & solutions of the almond skin peeler machine

Low peeling rate of the peanut skin peeling machine

Possible causes:

- Insufficient soaking time or low water temperature.

- Uneven size of raw materials.

- Worn blades or a clogged blade holder.

Solutions:

- Extend soaking time and adjust water temperature.

- Sort the raw materials by size.

- Replace the blades and clean the rubber rollers.

Too many kernels in the peel

Possible causes: The discharge roller is positioned too high.

Solutions: Lower the discharge roller position to ensure close contact with the peel-squeezing shaft

Too much peel residue on the kernels

Possible causes: The discharge roller is positioned too low.

Solutions: Adjust the discharge roller height to ensure proper contact.

High percentage of broken or half kernels

Possible causes:

- The rubber roller gap is too small.

- Raw materials soaked for too long.

Solutions:

- Increase the roller gap.

- Strictly control the soaking time.

Unpeeled nuts are flowing out of the outlet

Possible causes:

- Damaged or improperly installed guide strips.

- Uneven size of raw materials.

Solutions:

- Replace or adjust the guide strips

- Grade the raw materials before peeling

In addition to wet-type almond skin peeler machines, we also have dry-type peeling machines suitable for peeling nuts such as peanuts after roasting.

If you are unsure which machine is best suited for your needs, please feel free to contact us. You can provide information about the raw materials you want to process and their intended use, and we will provide you with a customized solution.